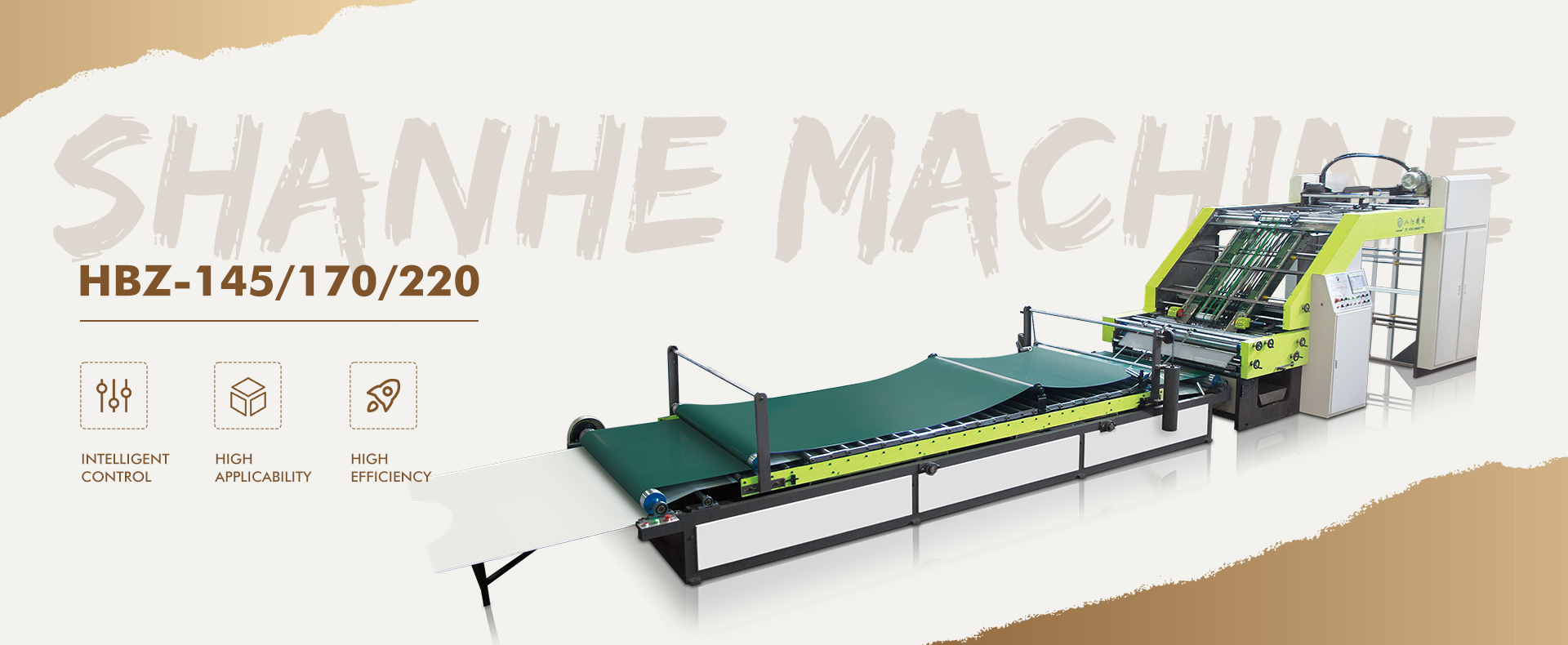

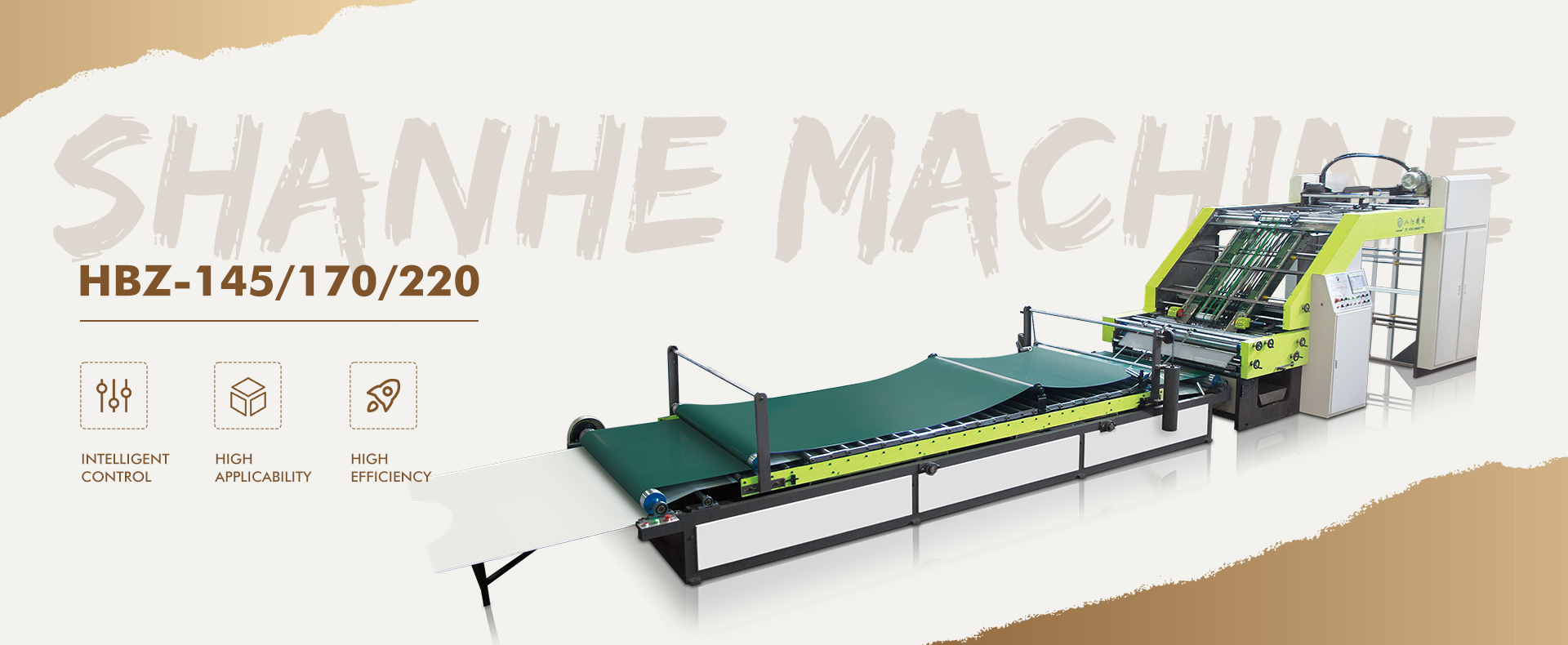

Matoorka Servo wuxuu ku shaqeeyaa suunka nuugista si uu u diro warqad hoose oo ay ku jiraan kartoon, loox cawlan iyo loox jiingado ah oo 3-geesood ah, 4-geesood ah, 5-geesood ah iyo 7-geesood ah oo leh A/B/C/D/E/F/N-flute. Dirista waa mid siman oo sax ah.

Iyada oo leh naqshad nuugid xooggan, mashiinku wuxuu soo diri karaa warqad dhumucdeedu u dhaxayso 250-1100g/㎡.

Qaybta quudinta xaashida hoose ee HBZ-170 waxay isticmaashaa bamka laba-geesoodka ah oo leh xakamaynta waalka laba-geesoodka ah, oo ujeeddadeedu tahay warqad ballackeedu yahay 1100+mm, waxay bilaabi kartaa bamka hawada labaad si loo kordhiyo mugga nuugista hawada, si fiican ugu shaqeyso gudbinta wareegyada iyo guddiga dahaarka qaro weyn.