Laminator ea flute e potlakileng ka boiketsetso

Re motlotlo ka khotsofalo e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona boleng bo holimo ba lihlahisoa le litšebeletso bakeng sa laminator ea flute e potlakileng ka boiketsetso, Ho fumaneha ho sa khaotseng ha thepa ea maemo a holimo hammoho le tšehetso ea rona e ikhethang ea pele le kamora thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o hola oa lefats'e.

Re motlotlo ka khotsofalo e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona boleng bo holimo ba lihlahisoa le litšebeletso bakeng saLaminator ea flute e potlakileng ea China e iketsang ka bo eona, re ntse re tšepa ka tieo ho theha kamano e ntle ea nako e telele ea khoebo le k'hamphani ea hau e hlomphehang eo u e nahanang, monyetla ona, o thehiloe khoebong e lekanang, e ruisang molemo ka bobeli le e putsang ho tloha joale ho fihlela nakong e tlang.

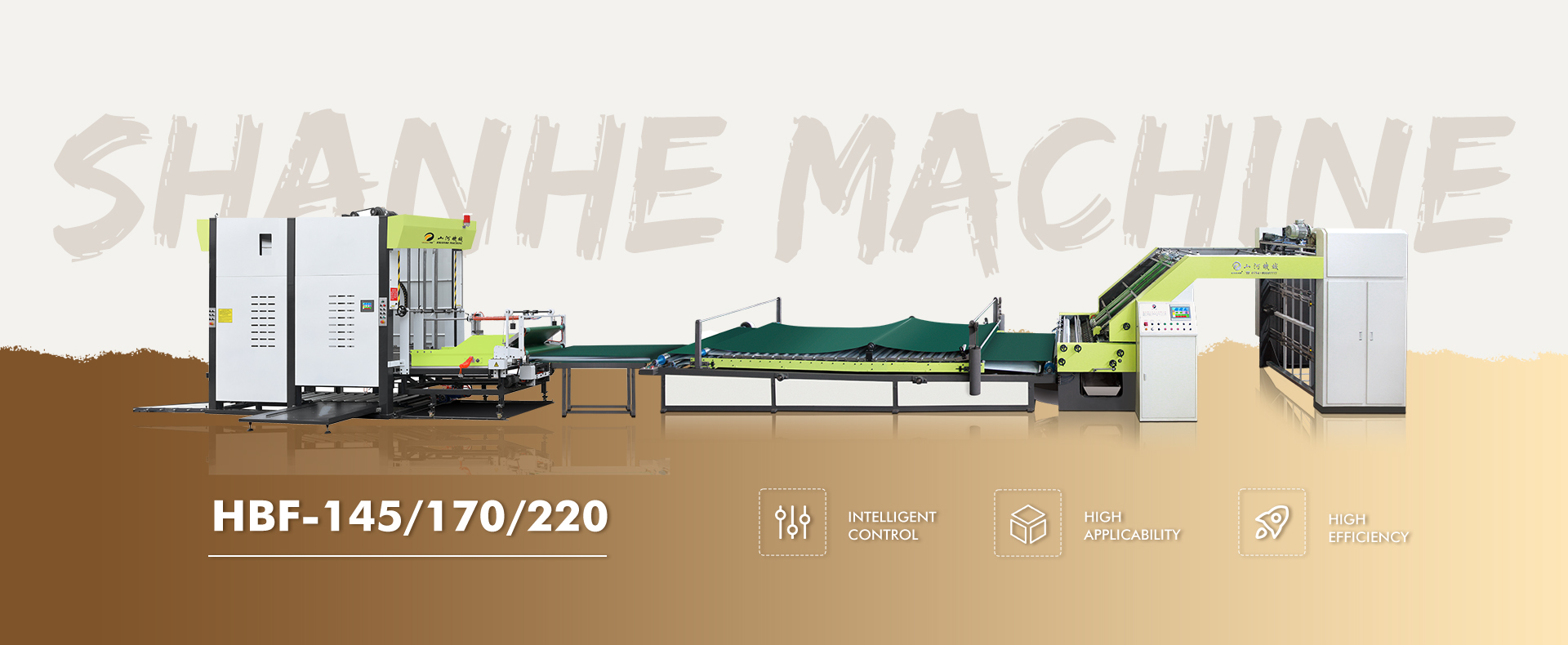

PONTŠO EA SEHLAHISOA

TLHAHISO

| HBF-145 | |

| Boholo ba lakane bo phahameng (mm) | 1450 (Bophara) x 1300 (Bophara) / 1450 (Bophara) x 1450 (Bophara) |

| Boholo ba lakane bo bonyane (mm) | 360 x 380 |

| Botenya ba lakane bo holimo (g/㎡) | 128 – 450 |

| Botenya ba lakane bo ka tlase (mm) | 0.5 – 10 (ha ho kopanngwa khateboto ya laminate le khateboto, re hloka hore pampiri e ka tlase e be ka hodimo ho 250gsm) |

| Lakane e ka tlase e loketseng | Boto e nang le masenke (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply le 7-ply); boto e putsoa; khateboto; boto ea KT, kapa lamination ea pampiri ho ea pampiring |

| Lebelo le phahameng la ho sebetsa (m/min) | 160m/min (ha bolelele ba flute e le 500mm, mochini o ka fihla lebelong le phahameng ka ho fetisisa la 16000pcs/hr) |

| Ho nepahala ha lamination (mm) | ± 0.5 – ± 1.0 |

| Matla(kw) | 16.6 (ha e kenyelletse compressor ea moea) |

| Matla a Stacker (kw) | 7.5 (ha e kenyelletse compressor ea moea) |

| Boima ba 'mele (kg) | 12300 |

| Tekanyo ea mochini (mm) | 21500(L) x 3000(W) x 3000(H) |

| HBF-170 | |

| Boholo ba lakane bo phahameng (mm) | 1700 (Bophara) x 1650 (Bophara) / 1700 (Bophara) x 1450 (Bophara) |

| Boholo ba lakane bo bonyane (mm) | 360 x 380 |

| Botenya ba lakane bo holimo (g/㎡) | 128 – 450 |

| Botenya ba lakane bo ka tlase (mm) | 0.5-10mm (bakeng sa lamination ea khateboto ho ea khatebotong: 250+gsm) |

| Lakane e ka tlase e loketseng | Boto e nang le masenke (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply le 7-ply); boto e putsoa; khateboto; boto ea KT, kapa lamination ea pampiri ho ea pampiring |

| Lebelo le phahameng la ho sebetsa (m/min) | 160 m/min (ha o sebedisa pampiri ya boholo ba 500mm, mochini o ka fihla lebelong le phahameng ka ho fetisisa la 16000pcs/hr) |

| Ho nepahala ha lamination (mm) | ± 0.5mm ho isa ho ± 1.0mm |

| Matla(kw) | 23.57 |

| Matla a Stacker (kw) | 9 |

| Boima ba 'mele (kg) | 14300 |

| Tekanyo ea mochini (mm) | 23600 (L) x 3320 (Bophara) x 3000 (Bophara) |

| HBF-220 | |

| Boholo ba lakane bo phahameng (mm) | 2200 (Bophara) x 1650 (Bohareng) |

| Boholo ba lakane bo bonyane (mm) | 600 x 600 / 800 x 600 |

| Botenya ba lakane bo holimo (g/㎡) | 200-450 |

| Lakane e ka tlase e loketseng | Boto e nang le masenke (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply le 7-ply); boto e putsoa; khateboto; boto ea KT, kapa lamination ea pampiri ho ea pampiring |

| Lebelo le phahameng la ho sebetsa (m/min) | 130 m/motsotso |

| Ho nepahala ha lamination (mm) | < ± 1.5mm |

| Matla(kw) | 27 |

| Matla a Stacker (kw) | 10.8 |

| Boima ba 'mele (kg) | 16800 |

| Tekanyo ea mochini (mm) | 24800 (L) x 3320 (Bophara) x 3000 (Bophara) |

MELEMO

Sistimi ea taolo ea motsamao bakeng sa ho hokahanya le ho laola ka sehloohong.

Sebaka se fokolang sa maqephe a pampiri se ka ba 120mm.

Li-motor tsa Servo bakeng sa ho hokahanya boemo ba ho laminating ba maqephe a ka pele le a ka morao.

Sistimi ea ho latela maqephe ka boiketsetso, maqephe a holimo a latela maqephe a tlase.

Skrine se amang bakeng sa ho laola le ho beha leihlo.

Sesebelisoa sa ho kenya pele sa mofuta oa gantry bakeng sa ho beha lakane e ka holimo habonolo.

Moqapi oa pampiri o otlolohileng o ka etsa hore pampiri e amoheloe ka boiketsetso.

LIKAROLOANA

A. TAOLO E BOHLALE

● Molaoli oa Motion oa Parker oa Amerika o tlatsana le mamello ho laola ho hokahanya

● Mechini ea Servo ea YASKAWA ea Japane e lumella mochini ho sebetsa ka botsitso le ka potlako haholoanyane

C. KAROLO EA TAOLO

● Mohlokomeli oa Skrine ea ho Ama, HMI, ka mofuta oa CN/EN

● Beha boholo ba maqephe, fetola sebaka sa maqephe le ho beha leihlo boemo ba ts'ebetso

E. KAROLO EA PHETISO

● Mabanta a nako a tsoang linaheng tse ling a rarolla bothata ba ho lamination e sa nepahalang ka lebaka la ketane e senyehileng

Boto e nang le masenke B/E/F/G/C9-flute 2-ply ho isa ho 5-ply

Boto ea Duplex

Boto e Putsoa

H. KAROLO EA HO JARA PELE

● Ho bonolo ho beha qubu ea pampiri e ka holimo

● Enjene ea Servo ea YASKAWA ea Japane

LINTLHA TSA HBZ TSA MOETSI

LINTLHA TSA MOETSI OA LF

LF-145/165 Vertical Paper Stacker ke ea ho hokela ka laminator ea flute e potlakileng ho etsa mosebetsi oa ho bokella pampiri ka boiketsetso. E bokella sehlahisoa sa lamination se felileng ka har'a qubu ho latela bongata ba ho seta. Mochini o kopanya mesebetsi ea ho phetla pampiri nako le nako, ho beha pampiri ka lehlakoreng le ka pele holimo kapa ka morao holimo le ho e hlophisa; qetellong e ka sutumelletsa qubu ea pampiri ka boiketsetso. Ho fihlela joale, e thusitse lik'hamphani tse ngata tsa khatiso le tsa ho paka ho sebetsana le bothata ba khaello ea basebetsi, ho ntlafatsa boemo ba mosebetsi, ho boloka basebetsi ba bangata le ho eketsa haholo tlhahiso eohle.

A. SUB-STACKER

● Sebelisa mabanta a rabara a sephara ho e hokahanya le laminator bakeng sa ho sebetsa ka tsela e tsamaellanang.

● Beha palo e itseng ea ho bokella pampiri, ka ho fihlella palo eo, pampiri e tla romelloa ka bo eona ho yuniti e phetlang (ea pele e tlisoang).

● E phaphatha pampiri ho tloha ka pele le mahlakoreng a mabeli ho etsa hore pampiri e bokellane hantle.

● Sebaka se nepahetseng se thehiloeng theknolojing ea maqhubu a feto-fetohang.

● Pampiri e sutumetsoang ke enjene.

● Ho sutumelletsa pampiri ho sa haneleng.

C. YUNITI EA HO PHETOHA

● Ha pampiri e romelloa ka lekhetlo la pele ho yuniti e phetlang, enjene e phahamisang e tla phahamisa pampiri ho fihlela bophahamong ba ho e beha.

● Nakong ea ts'ebetso ea bobeli ea ho fana ka thepa, pampiri e tla romelloa ho stacker e kholo.

● Sebaka se nepahetseng se thehiloeng theknolojing ea maqhubu a feto-fetohang.

● Ho phetla pampiri ka enjene. Pampiri e ka beoa ka qubu e le 'ngoe e ka pele e shebile holimo le qubu e le 'ngoe e shebileng morao e shebile holimo ka ho fapanyetsana, kapa kaofela ka mahlakoreng a eona a ka pele e shebile holimo 'me kaofela ka mahlakoreng a eona a ka morao e shebile holimo.

● Sebelisa enjene ea maqhubu a feto-fetohang ho sutumelletsa pampiri.

● Lekeno la terei.

● Taolo ea skrine ea ho ama.

● Sebaka se ka morao, le ho penta pampiri ho tloha mahlakoreng a 3: lehlakore le ka pele, lehlakore le letšehali le lehlakore le letona.

● Sesebelisoa sa ho bokella lintho esale pele bakeng sa ho fana ka thepa ntle le ho emisa.

● Bolelele ba ho bokella pampiri bo ka fetoloa pakeng tsa 1400mm le 1750mm. Bolelele bo ka eketsoa ho latela litlhoko tsa bareki.

G. KAROLO EA HO TLISA

● Ha pampiri e tlala, enjene e tla ntsha qubu ea pampiri ka bo eona.

● Ka nako e ts'oanang, terei e se nang letho e tla phahamisoa ho ea boemong ba eona ba pele.

● Qubu ea pampiri e tla huloa ke jeke ea pallet ho tloha leralleng.

| Mofuta oa Mosebetsi | Tlhahiso ea Hora |

| Sekoli sa E se le seng | 9000-14800 ka hora |

| Flute e le 'ngoe ea B | 8500-11000 ka hora |

| Folutu ea E habeli | 9000-10000 ka hora |

| BE-flute ea ply tse 5 | 7000-8000 ka hora |

| 5 ply BC-flute | 6000-6500 ka hora |

| PS: Lebelo la stacker le itšetlehile ka botenya ba 'nete ba boto | |

Re motlotlo ka khotsofalo e phahameng ea bareki le kamohelo e pharaletseng ka lebaka la ho phehella ha rona boleng bo holimo ba lihlahisoa le litšebeletso bakeng sa laminator ea flute e potlakileng ka boiketsetso, ho fumaneha ho sa khaotseng ha thepa ea maemo a holimo hammoho le tšehetso ea rona e ikhethang ea pele le kamora thekiso ho netefatsa tlholisano e matla 'marakeng o ntseng o hola oa lefats'e.

Laminator ea flute ea lebelo le phahameng ka boiketsetso, re tšepile ka tieo ho theha kamano e ntle ea khoebo ea nako e telele le k'hamphani ea hau e hlomphehang eo u e nahanang, e thehiloe khoebong e lekanang, e ruisang molemo ka bobeli le e hlōlisang ho tloha joale ho fihlela nakong e tlang.