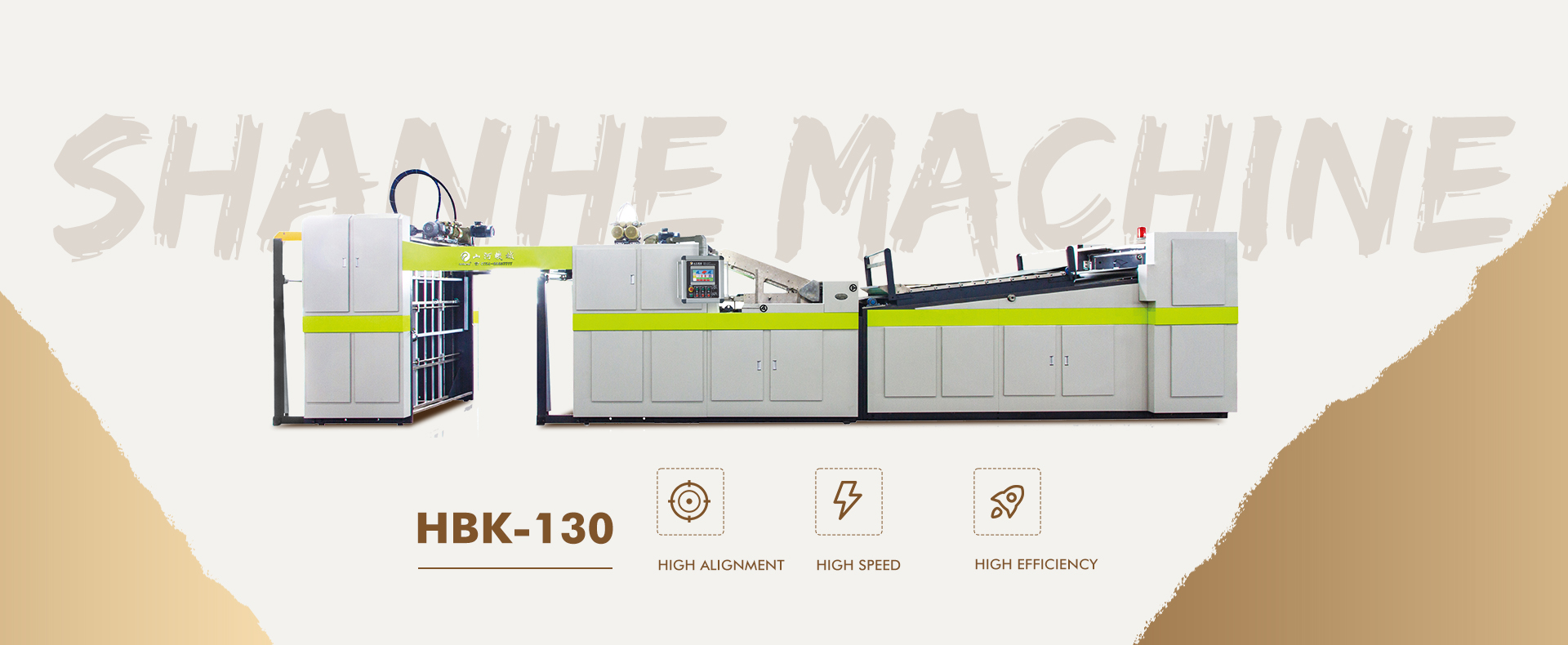

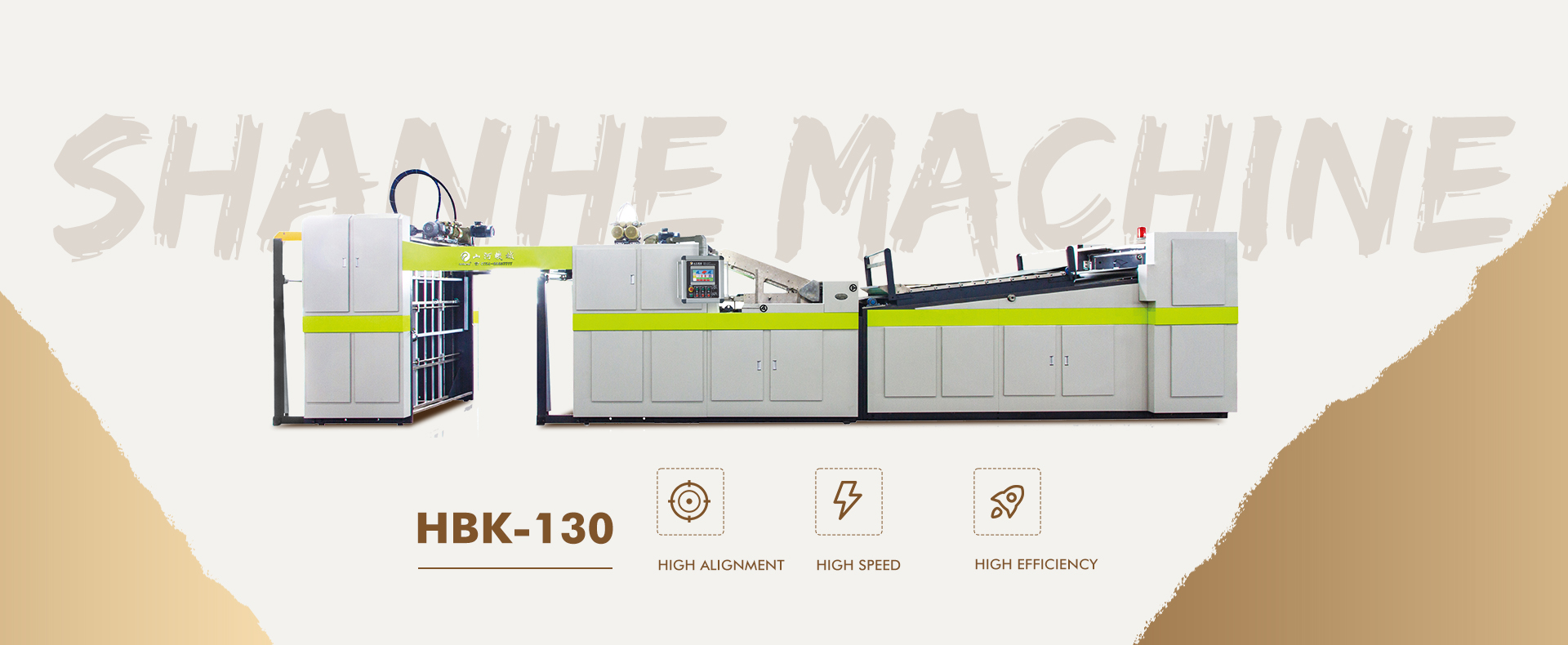

Yi amfani da samfurin SHANHE MACHINE mai zaman kansa wanda aka yi wa lasisin bincike da kuma aiki da shi: isar da abinci, tare da ƙirar firinta mai inganci, tsotsa biyu + hanyar tsotsar iska mai ɗaukar iska guda huɗu, mafi girman hanyar tsotsar ruwa 1100g/㎡ ta ƙasa tare da tsotsar ruwa daidai; duk masu ciyarwa sama da ƙasa suna da dandamalin ɗaukar kaya na nau'in gantry, suna barin sarari da lokaci don takarda kafin lodawa, aminci da aminci. Yana biyan buƙatun gudu mai sauri gaba ɗaya.

Sabuwar tsarin kariya ta atomatik na musamman:

1. Idan aka mayar da mai ciyarwa zuwa sifili, saurin zai ragu ta atomatik don rage tasirin mai ciyarwa.

2. Idan ba a sake saita na'urar ciyarwa ba, injin ba zai fara aiki ba don hana ɓarnar takarda wanda ke haifar da matsala.

3. Idan injin ya ji babu takardar saman da aka aika, mai ciyar da takardar ƙasa zai tsaya; idan takardar ƙasa ta riga ta aika, ɓangaren lamination zai tsaya ta atomatik don tabbatar da cewa ba za a aika takardar manne zuwa sashin matsewa ba.

4. Injin zai tsaya ta atomatik idan saman da ƙasan takardar sun makale.

5. Muna ƙara saitin bayanan diyya na matakin ciyar da takardar ƙasa don daidaita daidaiton.