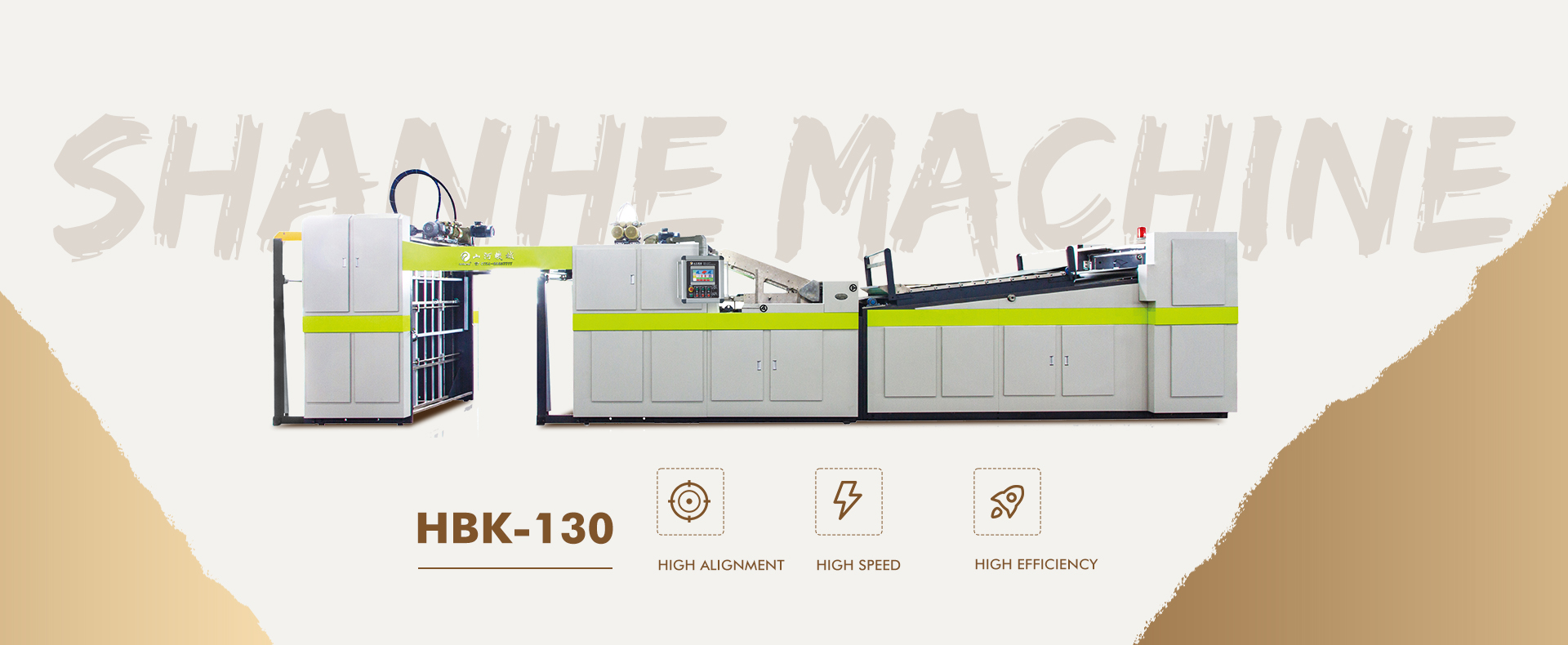

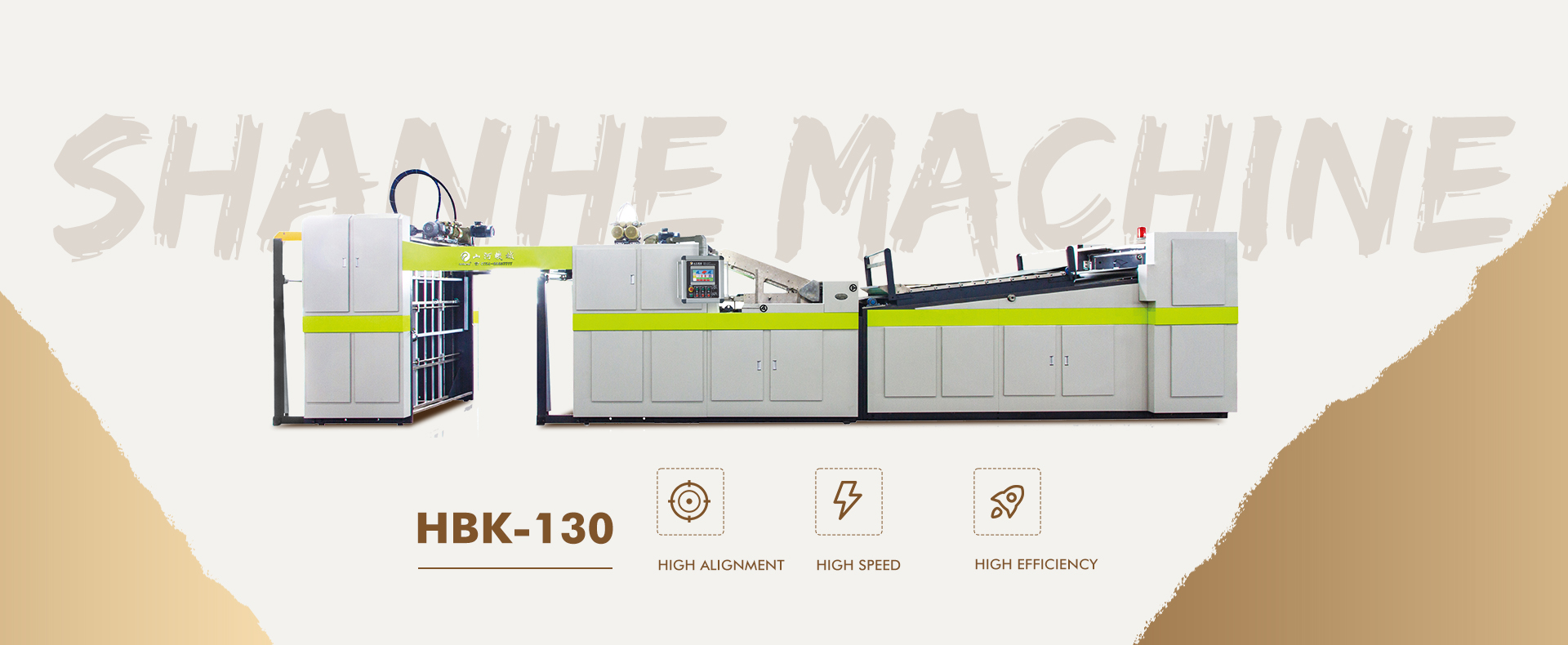

Use SHANHE MACHINE’s independent R&D patented product: feeder conveying, with high end printer use feeder’s design concept, double suction + four conveying air suction strengthened feeding way, maximally can suck 1100g/㎡ bottom sheet with precision suction; up and down feeders all have gantry-type pre-loading platform, leave space and time for pre-loading paper, safe and reliable. It totally satisfies high speed running’s requirements.

New special automatic protection system:

1. when feeder is return to zero, speed will slow down automatically to reduce the impact to the feeder.

2. If feeder is not reset, machine will not start so that to prevent paper waste which caused by malfunction.

3. If machine senses no top sheet was sent, bottom sheet feeder will stop; if bottom sheet already sends, lamination part will stop automatically to ensure no glued sheet will not be sent to the pressing part.

4. Machine will stop automatically if top and bottom sheet stuck.

5. We add bottom sheet feeder phase compensation data setting to make the alignment more precise.