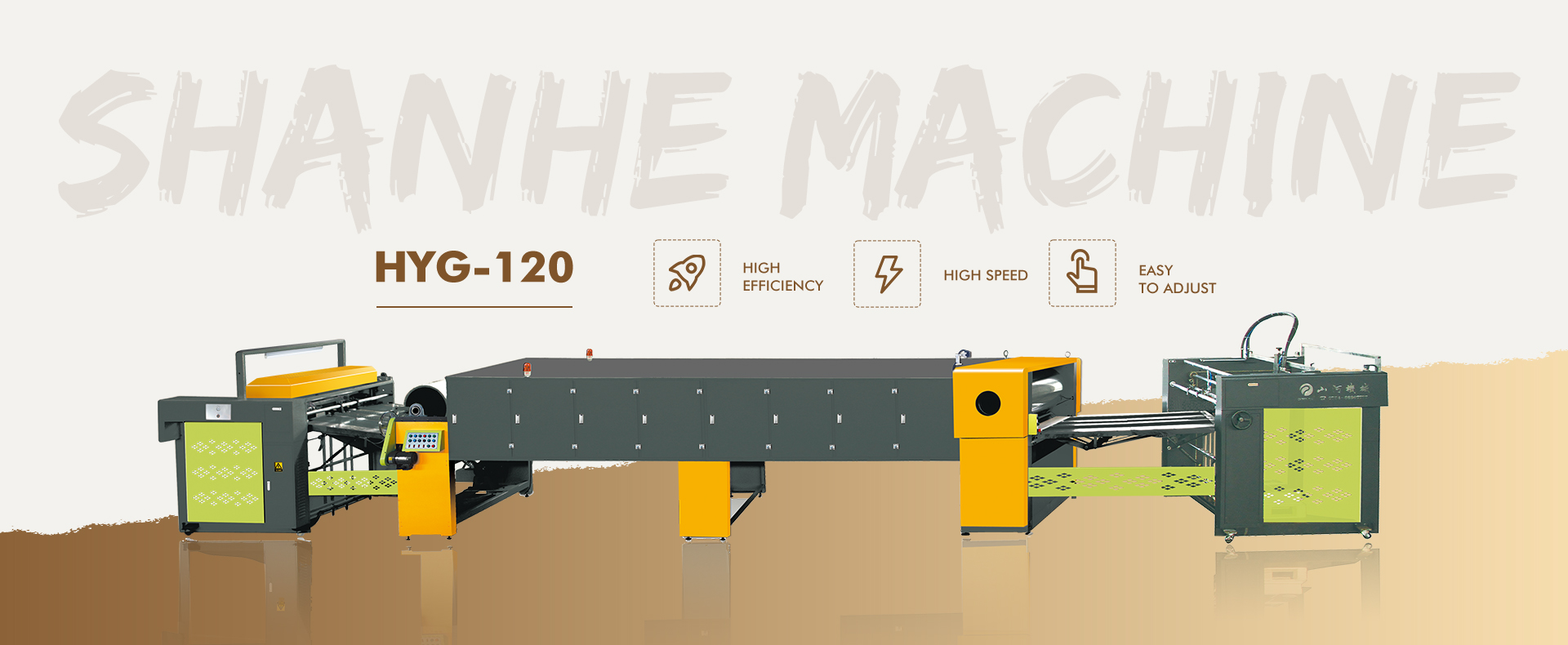

① Mun ƙara injina guda biyu waɗanda za su iya daidaita matsin lambar bel ɗin ta atomatik (wasu masu samar da kayayyaki galibi suna amfani da daidaita ƙafafun hannu).

② Muna ƙara na'urar hura iska don taimakawa zanen takarda su fito daga bel ɗin ƙarfe su gudu zuwa wurin tara takarda.

③ Mun magance matsalar fasaha cewa ba za a iya haɗa injin calendering na yau da kullun zuwa sashin ciyarwa ta atomatik da kuma stacker na atomatik ba.

④ Muna tsawaita allon gap gap don tattara zanen takarda bayan sun huce.