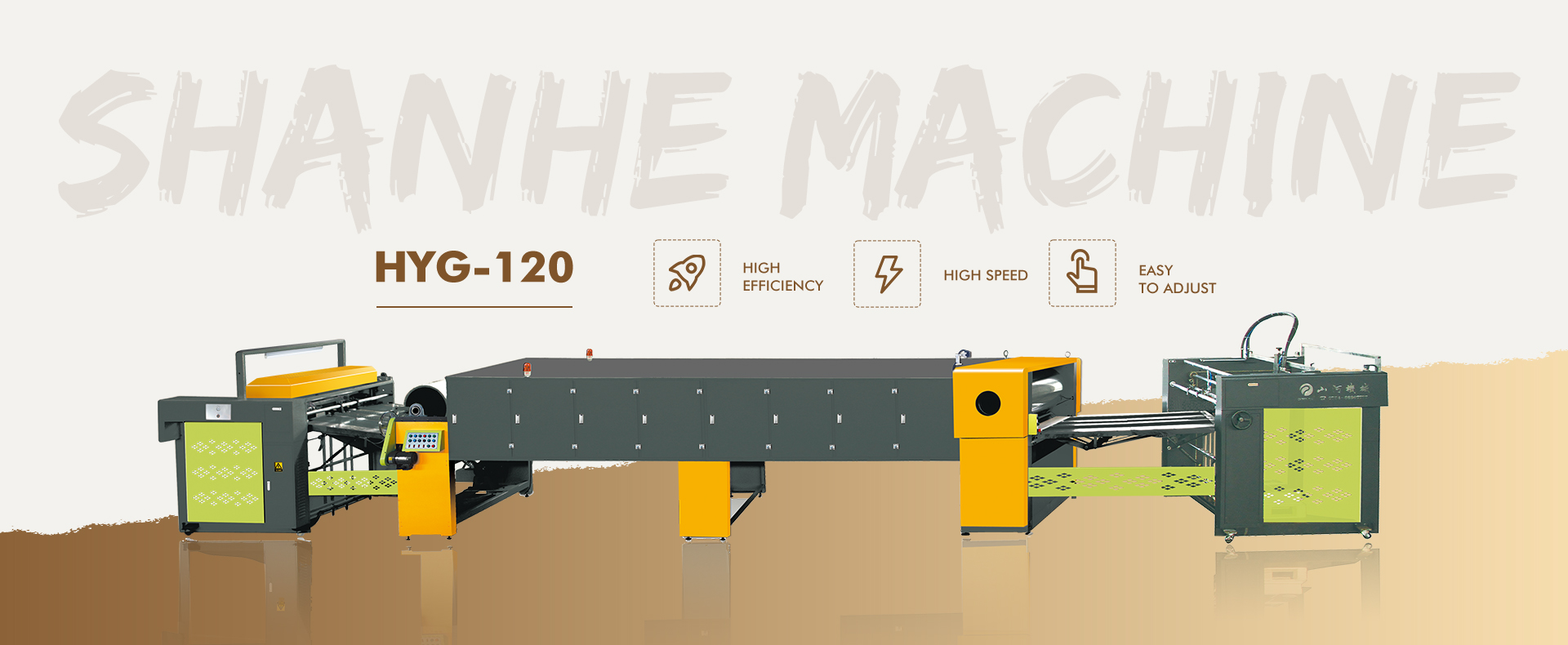

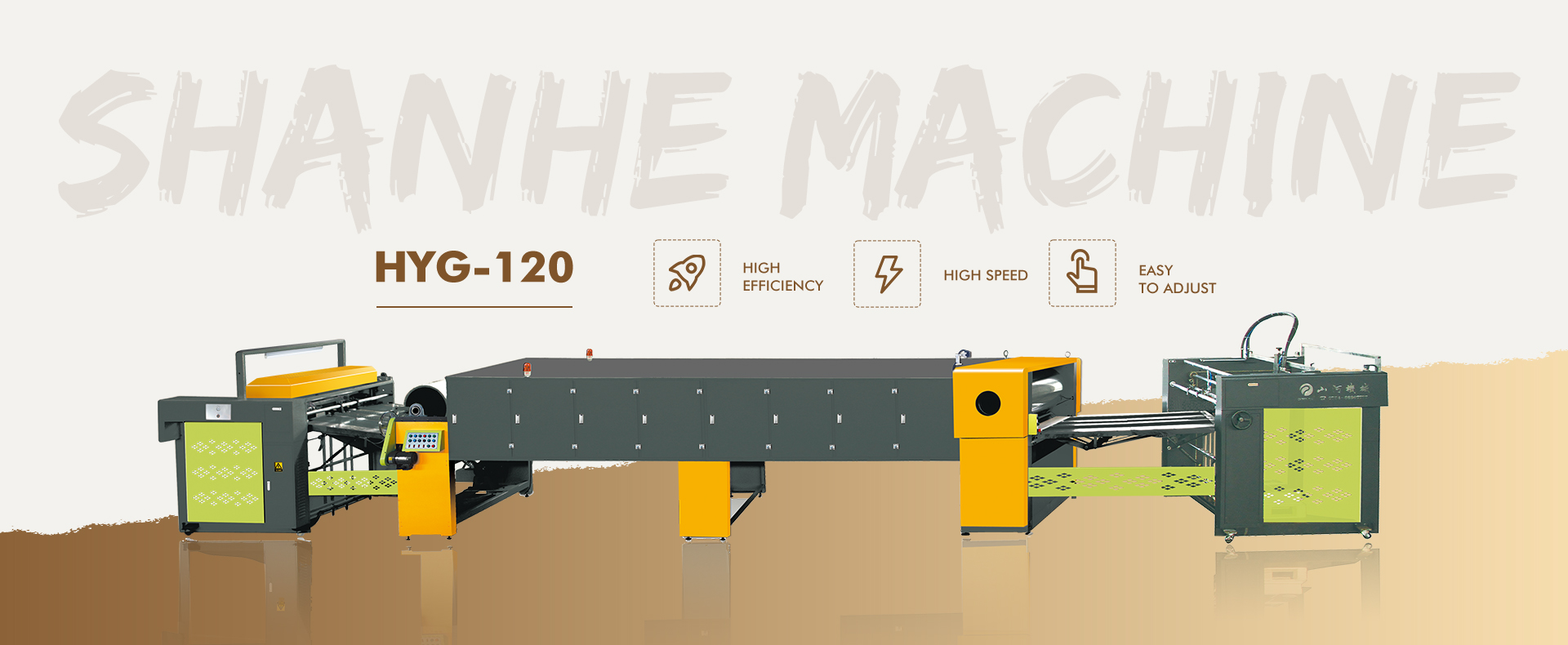

① We add two motors which can automatically adjust the belt’s tension (other suppliers use mostly manual wheel adjusting).

② We add an air blowing device to help paper sheets better get off from the steel belt and run to the paper stacker.

③ We solve the technical problem that normal calendering machine cannot be connected to the automatic feeding part and automatic stacker.

④ We prolong the gap bridge board for collecting the paper sheets after they are cooling down.