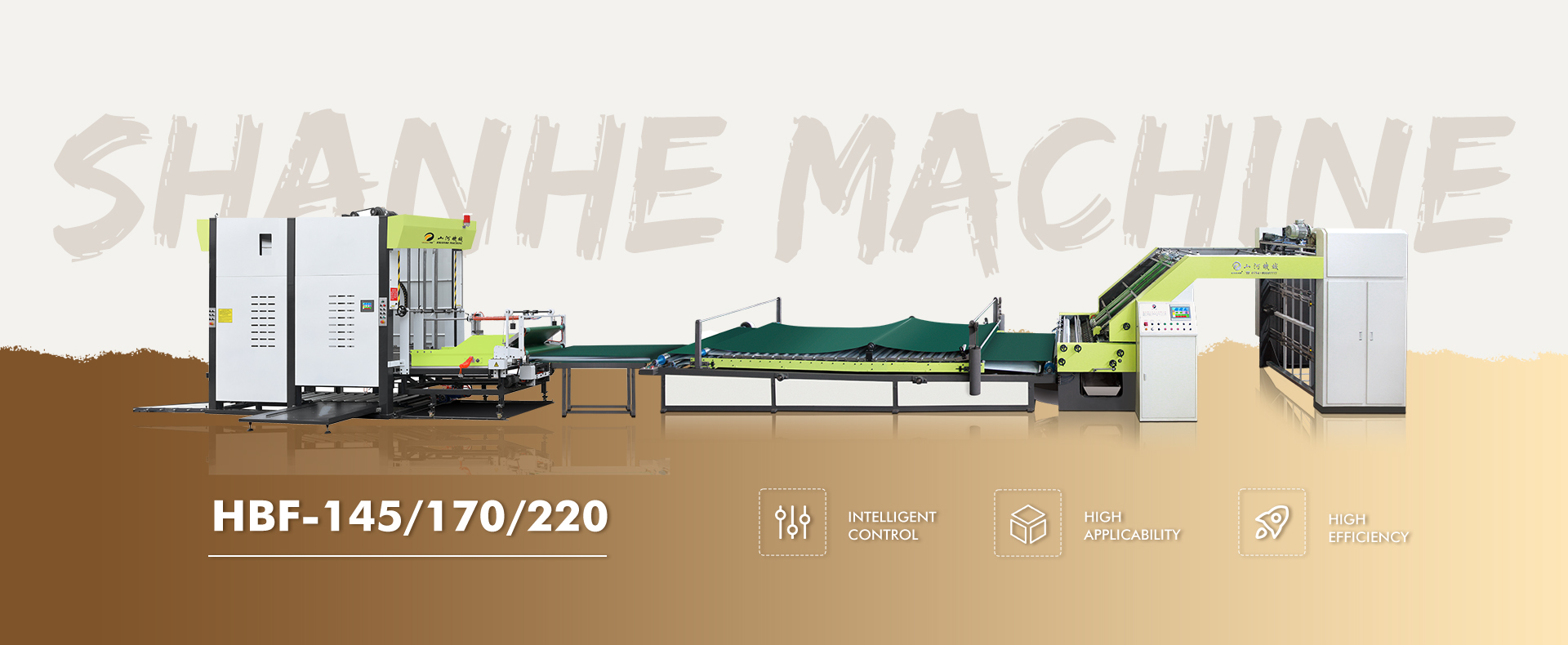

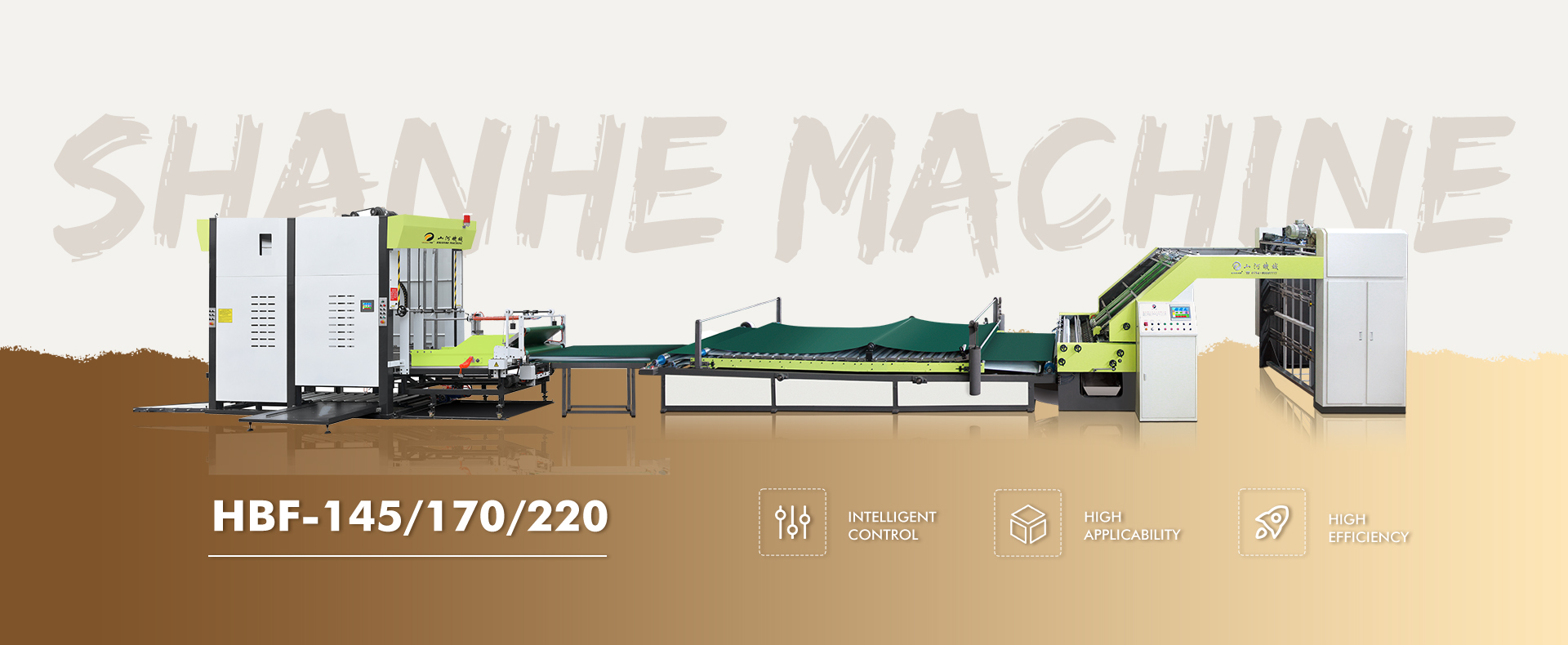

Enjene ea Servo e khanna mabanta a ho hula ho romela pampiri e ka tlase e kenyeletsang khateboto, boto e putsoa le boto e kobehileng ea 3-ply, 4-ply, 5-ply le 7-ply e nang le flute ea A/B/C/D/E/F/N. Ho romelloa ho boreleli ebile ho nepahetse.

Ka moralo o matla oa ho hula, mochini o ka romela pampiri e nang le botenya bo pakeng tsa 250-1100g/㎡.

Karolo e ka tlase ea ho fepa pampiri ea HBZ-170 e sebelisa pompo ea li-vortex tse peli e nang le taolo ea valve ea solenoid tse peli, e shebaneng le pampiri ea bophara ba 1100+mm, e ka qala pompo ea bobeli ea moea ho eketsa bophahamo ba monya moea, e sebetsa hantle ho tsamaiseng ho sotha le boto e teteaneng ea corrugation.