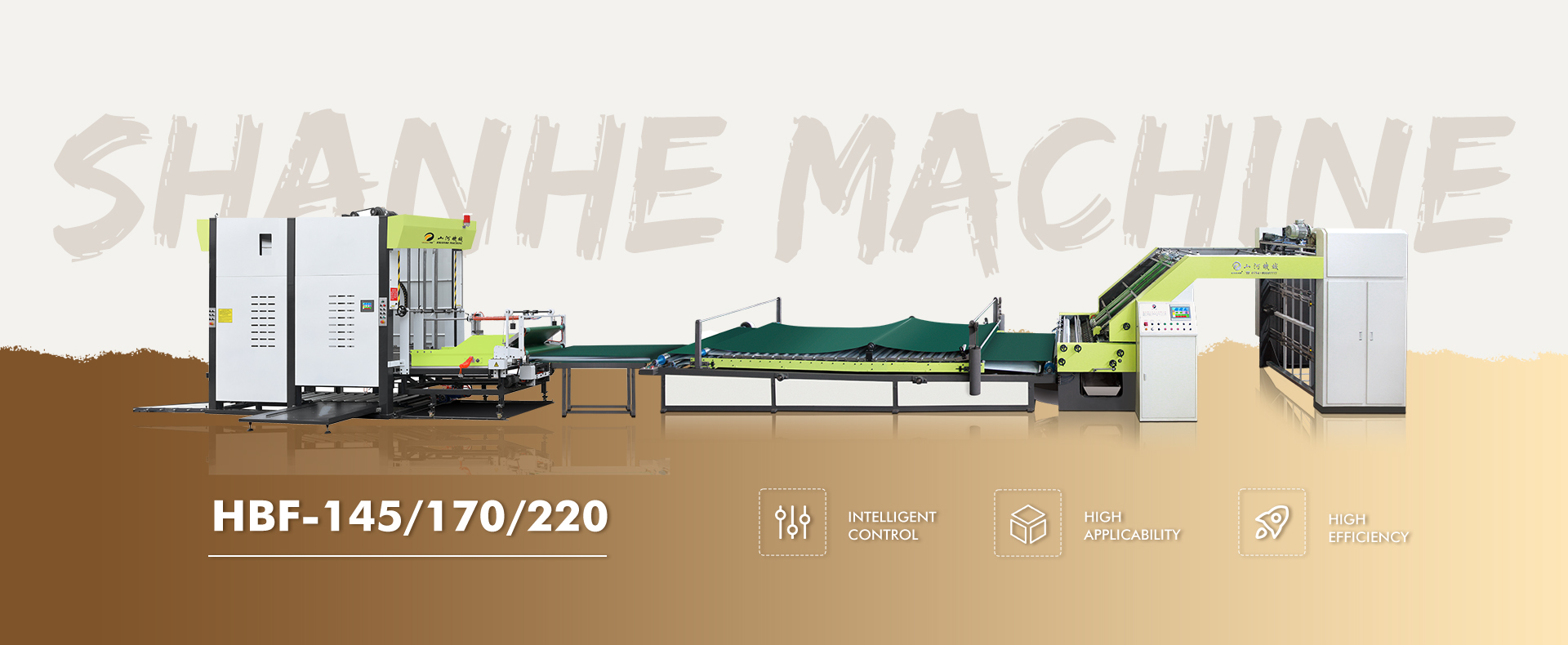

Massive Selection for Automatic High Speed Flute Laminator

Each individual member from our large performance revenue crew values customers’ needs and company communication for Massive Selection for Automatic High Speed Flute Laminator, To improved expand sector, we sincerely invite ambitious individuals and corporations to join as an agent.

Each individual member from our large performance revenue crew values customers’ needs and company communication for China Auto Flute Laminating Machine, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

PRODUCT SHOW

SPECIFICATION

| HBF-145 | |

| Max. sheet size(mm) | 1450 (W) x 1300 (L) / 1450 (W) x 1450 (L) |

| Min. sheet size(mm) | 360 x 380 |

| Top sheet thickness(g/㎡) | 128 – 450 |

| Bottom sheet thickness(mm) | 0.5 – 10 (when laminate cardboard to cardboard, we require bottom sheet to be above 250gsm) |

| Suitable bottom sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply); grey board; cardboard; KT board, or paper to paper lamination |

| Max. working speed(m/min) | 160m/min (when flute length is 500mm, machine can reach max. speed 16000pcs/hr) |

| Lamination accuracy(mm) | ±0.5 – ±1.0 |

| Power(kw) | 16.6 (not include air compressor) |

| Stacker power(kw) | 7.5 (not include air compressor) |

| Weight(kg) | 12300 |

| Machine dimension(mm) | 21500(L) x 3000(W) x 3000(H) |

| HBF-170 | |

| Max. sheet size(mm) | 1700 (W) x 1650 (L) / 1700 (W) x 1450 (L) |

| Min. sheet size(mm) | 360 x 380 |

| Top sheet thickness(g/㎡) | 128 – 450 |

| Bottom sheet thickness(mm) | 0.5-10mm (for cardboard to cardboard lamination: 250+gsm) |

| Suitable bottom sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply); grey board; cardboard; KT board, or paper to paper lamination |

| Max. working speed(m/min) | 160 m/min (when running 500mm size paper, machine can reach max. speed 16000pcs/hr) |

| Lamination accuracy(mm) | ±0.5mm to ±1.0mm |

| Power(kw) | 23.57 |

| Stacker power(kw) | 9 |

| Weight(kg) | 14300 |

| Machine dimension(mm) | 23600 (L) x 3320 (W) x 3000(H) |

| HBF-220 | |

| Max. sheet size(mm) | 2200 (W) x 1650 (L) |

| Min. sheet size(mm) | 600 x 600 / 800 x 600 |

| Top sheet thickness(g/㎡) | 200-450 |

| Suitable bottom sheet | Corrugated board (A/B/C/D/E/F/N-flute, 3-ply, 4-ply, 5-ply and 7-ply); grey board; cardboard; KT board, or paper to paper lamination |

| Max. working speed(m/min) | 130 m/min |

| Lamination accuracy(mm) | < ± 1.5mm |

| Power(kw) | 27 |

| Stacker power(kw) | 10.8 |

| Weight(kg) | 16800 |

| Machine dimension(mm) | 24800 (L) x 3320 (W) x 3000 (H) |

ADVANTAGES

Motion control system for coordinating and main controlling.

Minimal sheets distance can be 120mm.

Servo motors for alignment of top sheets’ front and back laminating position.

Automatic sheets tracking system, top sheets trace bottom sheets.

Touch screen for controlling & monitoring.

Gantry type pre-loading device for easy placing top sheet.

Vertical Paper Stacker can realize automatic paper receiving.

FEATURES

A. INTELLIGENT CONTROL

● American Parker Motion Controller complement the tolerance to control the alignment

● Japanese YASKAWA Servo Motors allow machine to perform more stable and fast

C. CONTROLLING SECTION

● Touch Screen Monitor, HMI, with CN/EN version

● Set sheets size, change sheets distance and monitoring the operation state

E. TRANSMISSION SECTION

● Imported timing belts solve problem of inaccurate lamination due to the worn-out chain

Corrugated Board B/E/F/G/C9-flute 2-ply to 5-ply

Duplex Board

Grey Board

H. PRE-LOADING SECTION

● Easier for placing top sheet pile

● Japanese YASKAWA Servo Motor

MODEL HBZ DETAILS

MODEL LF DETAILS

LF-145/165 Vertical Paper Stacker is for connecting with high speed flute laminator to realize automatic paper stacking function. It stacks up the finished lamination product into a pile as per setting quantity. Machine combines the functions of flipping paper intermittently, stacking paper on front side up or back side up and tidy stacking; at the end it can automatic push out the paper pile. Till now, it has helped many printing and packaging companies to deal with the labor shortage problem, optimize the working state, save labor intense and highly increase the total output.

A. SUB-STACKER

● Use wide rubber belts to connect it with laminator for running synchronously.

● Set a certain paper stacking quantity, by reach that number, paper will be sent to the flipping unit automatically (the first delivering).

● It pat the paper from the front and two sides to make the paper piled neatly.

● Accurate positioning based on variable frequency technology.

● Paper pushing driven by motor.

● Non-resistant paper pushing.

C. FLIPPING UNIT

● When paper first be sent to the flipping unit, the lifting motor will raise the paper to the setting height.

● During the second delivering process, paper will be sent to the main stacker.

● Accurate positioning based on variable frequency technology.

● Motor-driven paper flipping. Paper can be stacked with one pile front side up and one pile back side up alternately, or all with their front sides up and all with their back sides up.

● Use variable frequency motor to push paper.

● Tray inlet.

● Touch screen control.

● Rear positioning, and paper patting from 3 sides: front side, left side and right side.

● Pre-stacking device for non-stop delivering.

● Paper stacking height is adjustable between 1400mm to 1750mm. The height can be increased according to customer requirements.

G. DELIVERING PART

● When paper stacker is full, motor will drive paper pile out automatically.

● At the same time, the empty tray will be lifted up to original position.

● Paper pile will be pulled away by a pallet jack from the slope.

|

Job Type |

Hourly Output |

|

Single E-flute |

9000-14800 p/hr |

|

Single B-flute |

8500-11000 p/hr |

|

Double E-flute |

9000-10000 p/hr |

|

5 ply BE-flute |

7000-8000 p/hr |

|

5 ply BC-flute |

6000-6500 p/hr |

| PS: stacker’s speed depends on the actual thickness of the board | |

Each individual member from our large performance revenue crew values customers’ needs and company communication for Massive Selection for Automatic High Speed Flute Laminator, to improved expand sector, we sincerely invite ambitious individuals and corporations to join as an agent.

Massive Selection for China Auto Flute Laminating Machine, our products are widely sold to Africa, Middle East, Southeast Asia, Russia, Europe, South America, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!