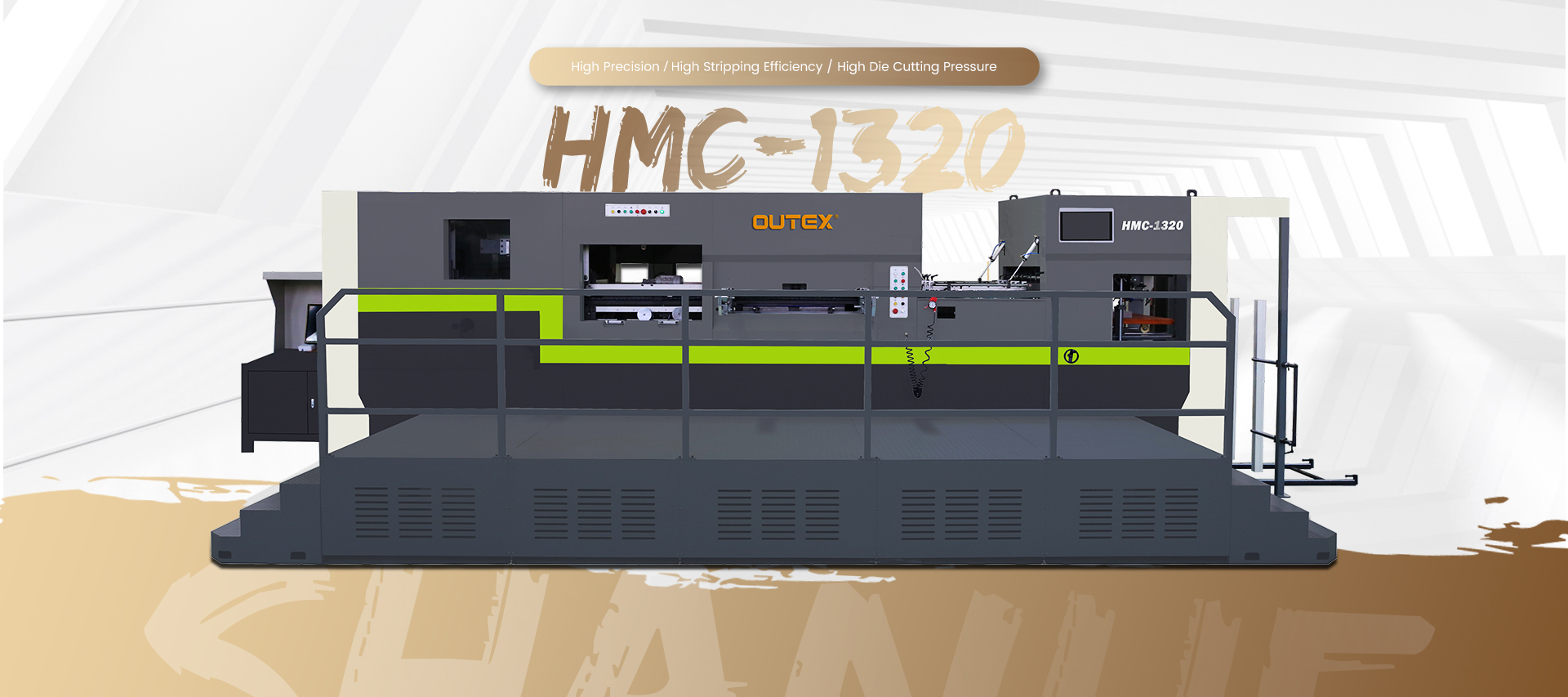

Umshini Wokusika Ozenzakalelayo we-HMC-1320

ISICELO

| I-HMC-1320 | |

| Usayizi wephepha ophezulu | 1320 x 960mm |

| Usayizi wephepha omncane | 500 x 450mm |

| Usayizi omkhulu wokusika idayisi | 1300 x 950mm |

| Isivinini esiphezulu sokugijima | 6000 S/H(iyahlukahluka ngokuya ngosayizi wesakhiwo) |

| Isivinini somsebenzi wokususa | 5500 S/H (aries ngokuya ngosayizi wesakhiwo) |

| Ukunemba kokusika ngodayi | ± 0.20mm |

| Ukuphakama kwenqwaba yokufaka iphepha (kufaka phakathi ibhodi lephansi) | 1600mm |

| Ukuphakama kwenqwaba yokukhipha iphepha (kufaka phakathi ibhodi lephansi) | 1150mm |

| Ubukhulu bephepha | ikhadibhodi: 0.1-1.5mm ibhodi ehlanganisiwe: ≤10mm |

| Uhla lwengcindezi | 2mm |

| Ukuphakama komugqa we-blade | 23.8mm |

| Isilinganiso | 380±5%VAC |

| Ukucindezela okuphezulu | 350T |

| Inani lomoya ocindezelwe | ≧0.25㎡/ngomzuzu ≧0.6mpa |

| Amandla amakhulu enjini | 15KW |

| Amandla aphelele | 25KW |

| Isisindo | 19T |

| Usayizi womshini | Akubandakanyi i-pedal yokusebenza kanye nengxenye yokubeka kusengaphambili: 7920 x 2530 x 2500mm Faka i-pedal yokusebenza kanye nengxenye yokubeka kusengaphambili: 8900 x 4430 x 2500mm |

IMINININGWANE

Lo mshini womuntu uzothuthukisa ukusebenza kahle komshini ngohlelo lokulawula ukunyakaza oluhlanganiswe kahle ne-servo motor, okuqinisekisa ukuthi ukusebenza konke kungenziwa kahle futhi kube lula. Usebenzisa futhi ukwakheka okuhlukile kwesakhiwo sokumunca iphepha ukwenza umshini uzivumelanise nebhodi lephepha eligobile eliqinile. Ngedivayisi yokudla engayeki kanye nesengezo sephepha kukhulisa kakhulu ukusebenza kahle. Ngesihlanzi semfucuza esizenzakalelayo, singasusa kalula imiphetho emine kanye nembobo ngemva kokusika ngodayi. Wonke umshini usebenzisa izingxenye ezingenisiwe eziqinisekisa ukuthi ukusetshenziswa kwawo kuzinzile futhi kuhlala isikhathi eside.