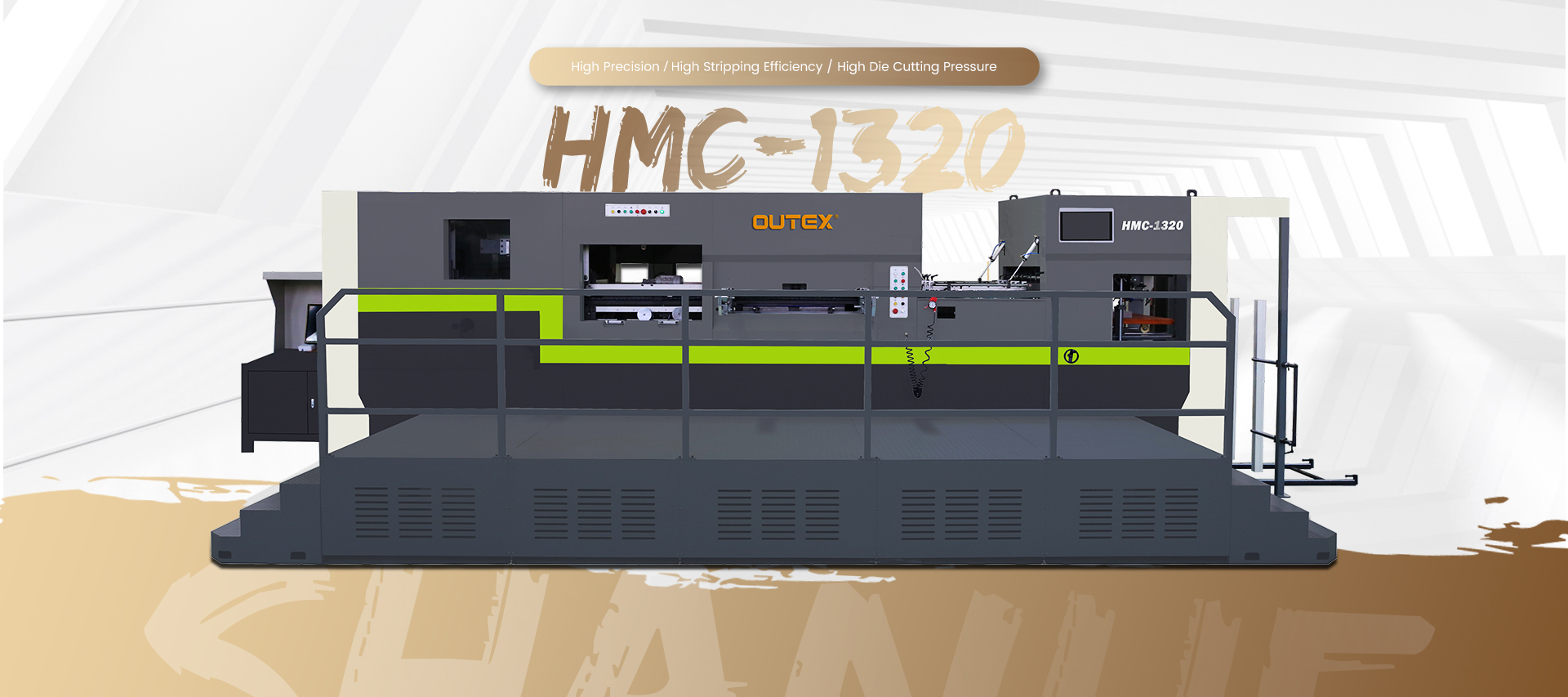

HMC-1320 Automatic Die Cutting Machine

SPECIFICATION

|

HMC-1320 |

|

| Max. paper size | 1320 x 960mm |

| Min. paper size | 500 x 450mm |

| Max. die cut size | 1300 x 950mm |

| Max. running speed | 6000 S/H(varies according to layout size) |

| Stripping work speed | 5500 S/H(aries according to layout size) |

| Die cut precision | ±0.20mm |

| Paper input pile height (including floor board) | 1600mm |

| Paper output pile height (including floor board) | 1150mm |

| Paper thickness | cardboard: 0.1-1.5mm

corrugated board: ≤10mm |

| Pressure range | 2mm |

| Blade line height | 23.8mm |

| Rating | 380±5%VAC |

| Max. pressure | 350T |

| The compressed air amount | ≧0.25㎡/min ≧0.6mpa |

| Main motor power | 15KW |

| Total power | 25KW |

| Weight | 19T |

| Machine size | Not include operation pedal and pre-stacking part: 7920 x 2530 x 2500mm

Include operation pedal and pre-stacking part: 8900 x 4430 x 2500mm |

DETAILS

This human-machine is going for improving the machine working efficiency by perfectly combined movement control system with servo motor, which ensure the whole operating can smooth and high efficiency. It also uses the unique design of paper suction structure to make the machine adapt to bent corrugated paperboard more stable. With non-stop feeding device and paper supplement it highly increases the working efficiency. With auto waste cleaner, it can easily remove the four edges and hole after die-cutting. The whole machine uses imported components which makes sure the more stable and durable using of it.