With so much of today’s carton production being destined for auto-erection lines, ensuring accurate, reliable opening of your finished product has never been more important.

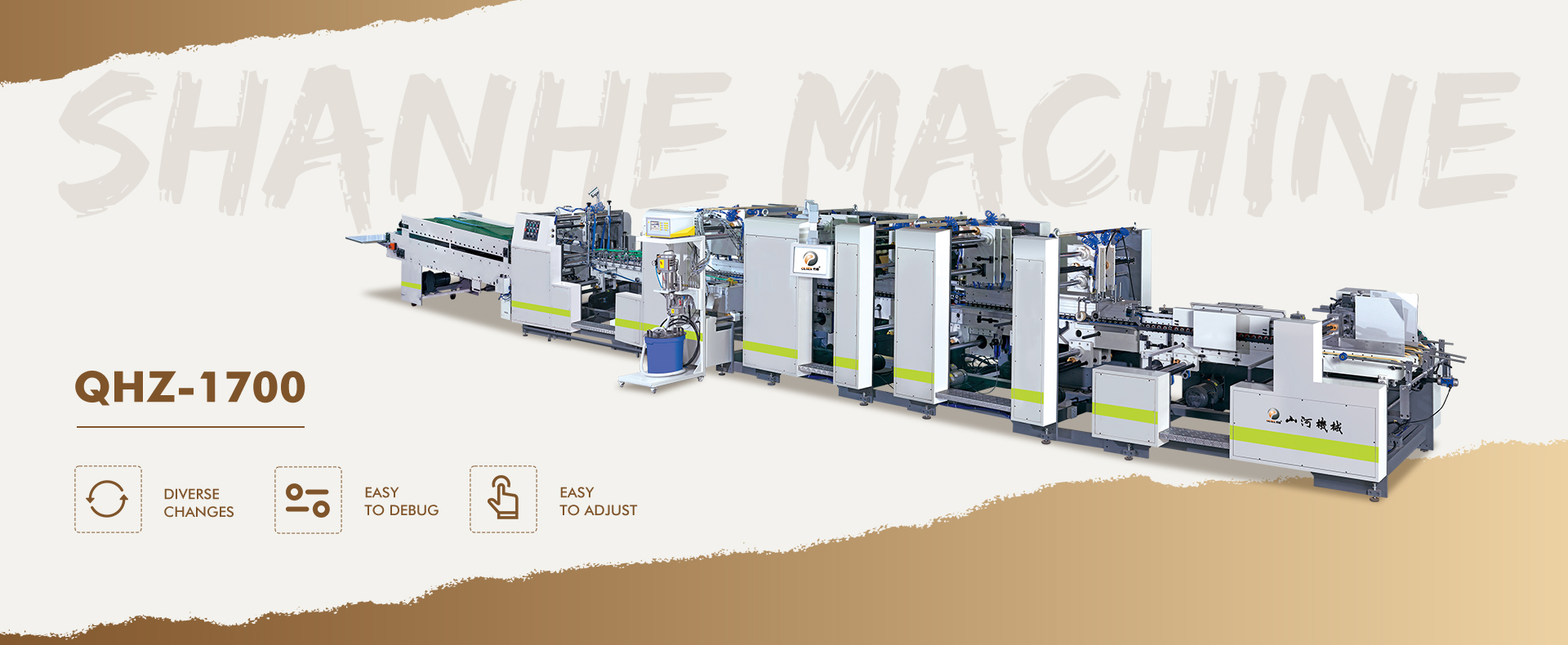

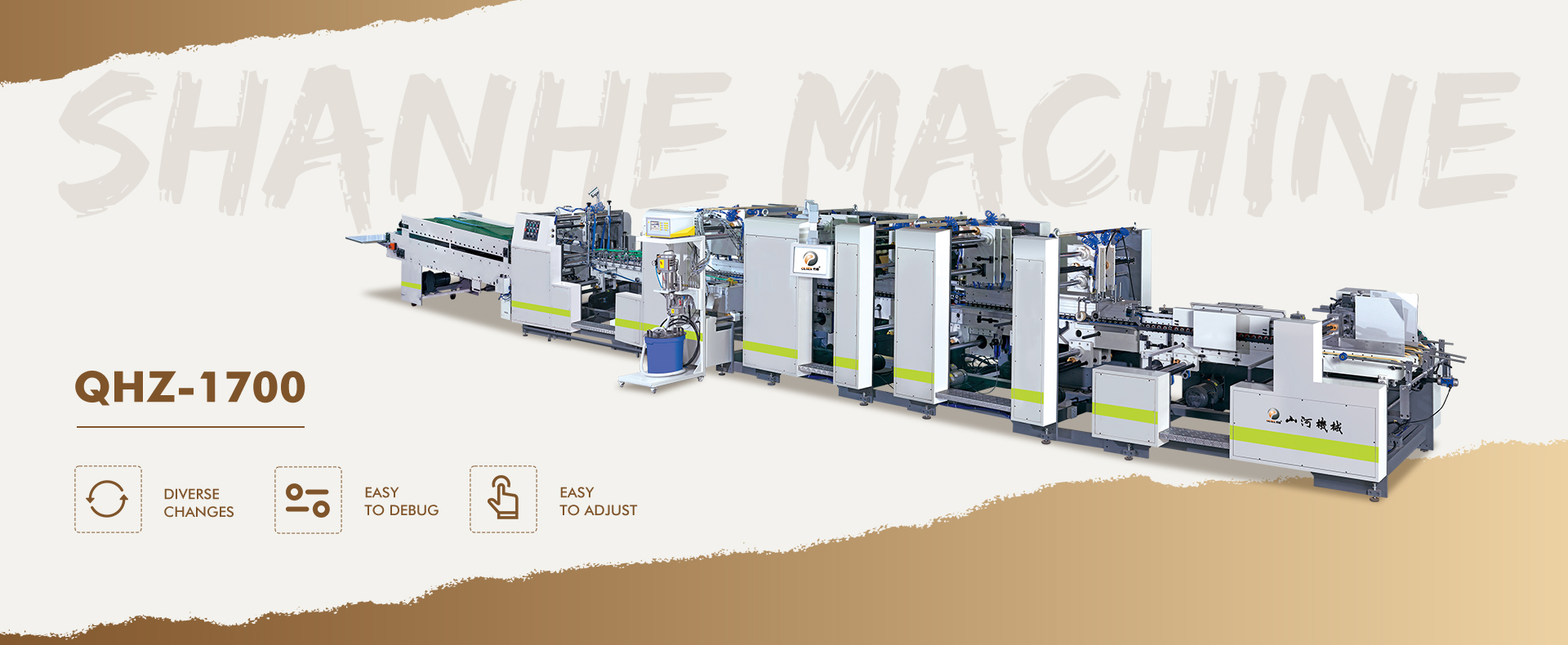

1) Long pre-folder

2) Extra wide lower left-hand belt

3) Unique design, protect the box surface

4) Up carrier is driven and pneumatic up/down system

5) Creasing system for die cutting lines