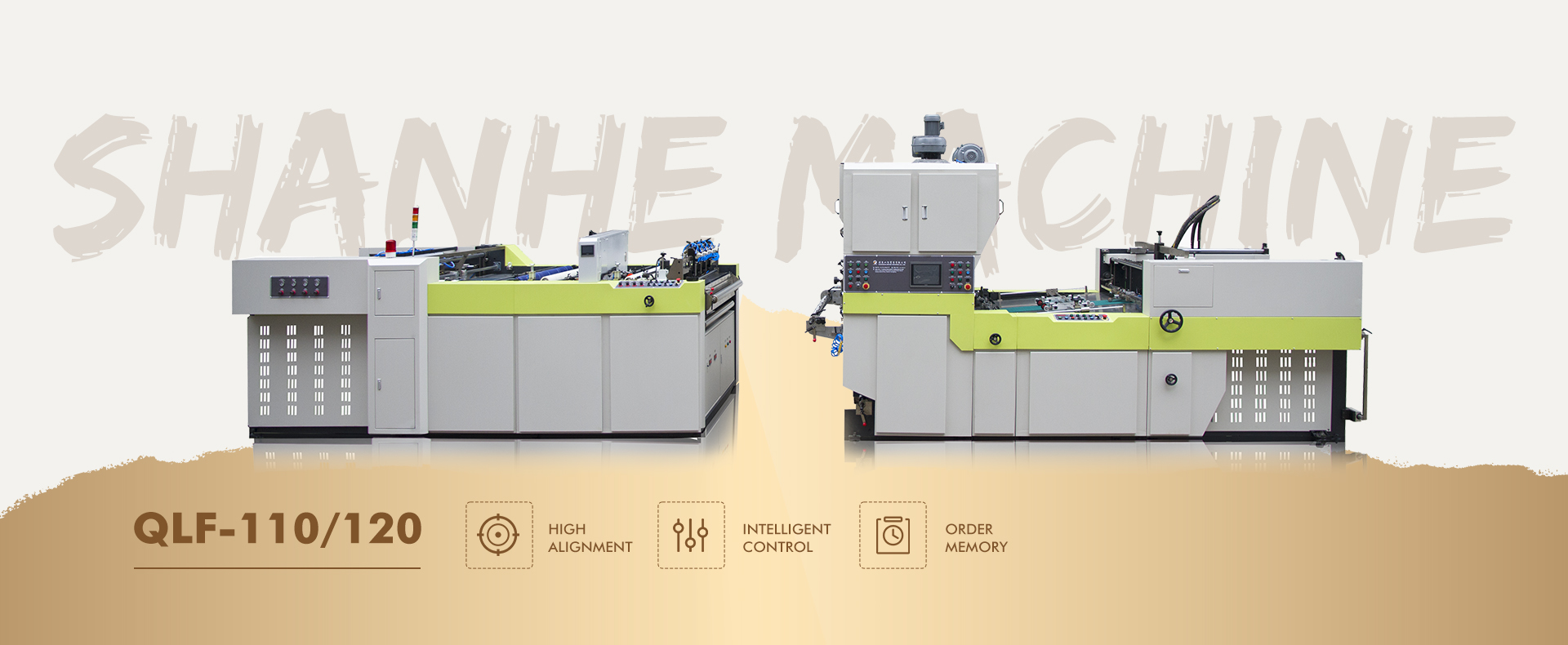

Servo shaft-less high speed feeder, suitable for all printing sheets, can run stably at high speed.

Large diameter roller design (800mm), use imported seamless tube surface with hard chrome plating, increase the film brightness, and thus improve product quality.

Electromagnetic heating mode: the heat utilization rate can reach 95%, so machine heats up twice faster than before, save electricity and energy.

Thermal energy circulation drying system, the whole machine uses 40kw/hr electricity consumption, save more energy.

Increase efficiency: intelligent control, production speed up to 100m/min.

Cost reduction: high precision coated steel roller design, precise control of glue coating amount, save glue and increase speed.