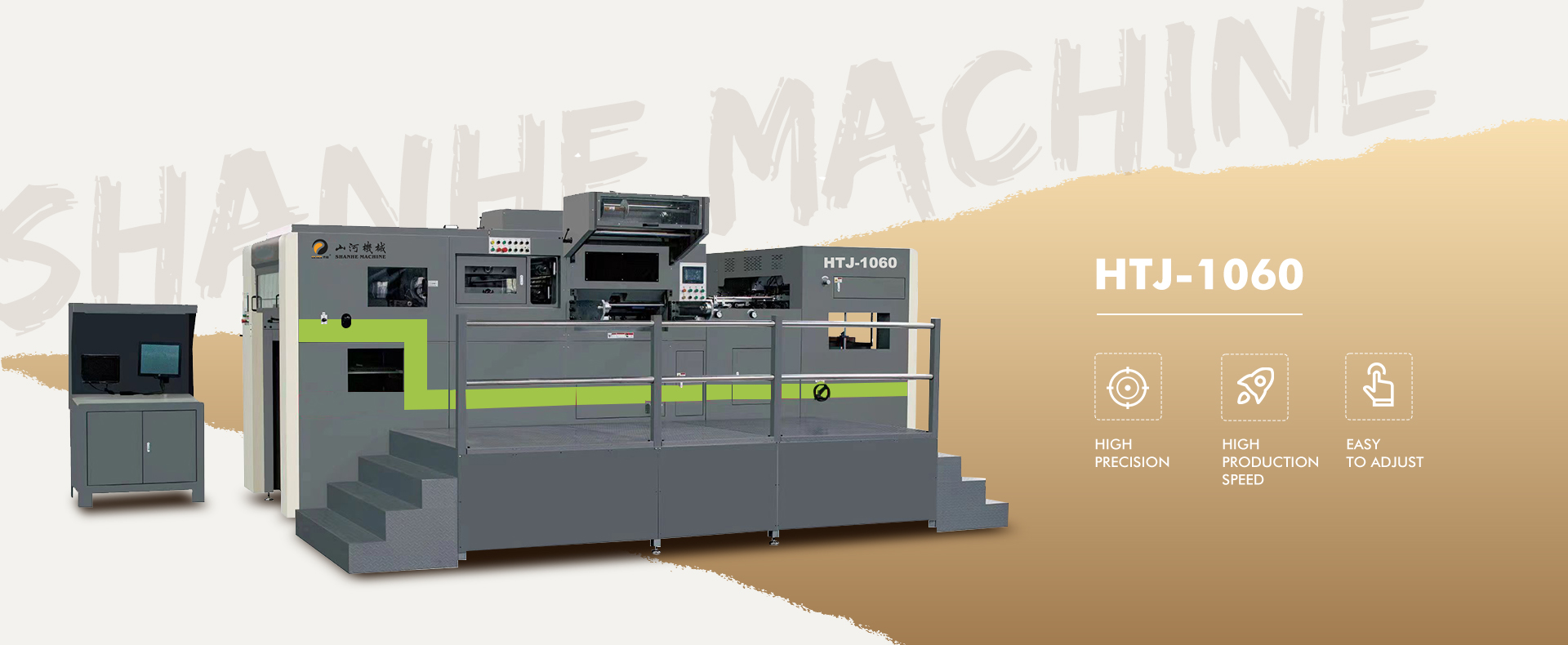

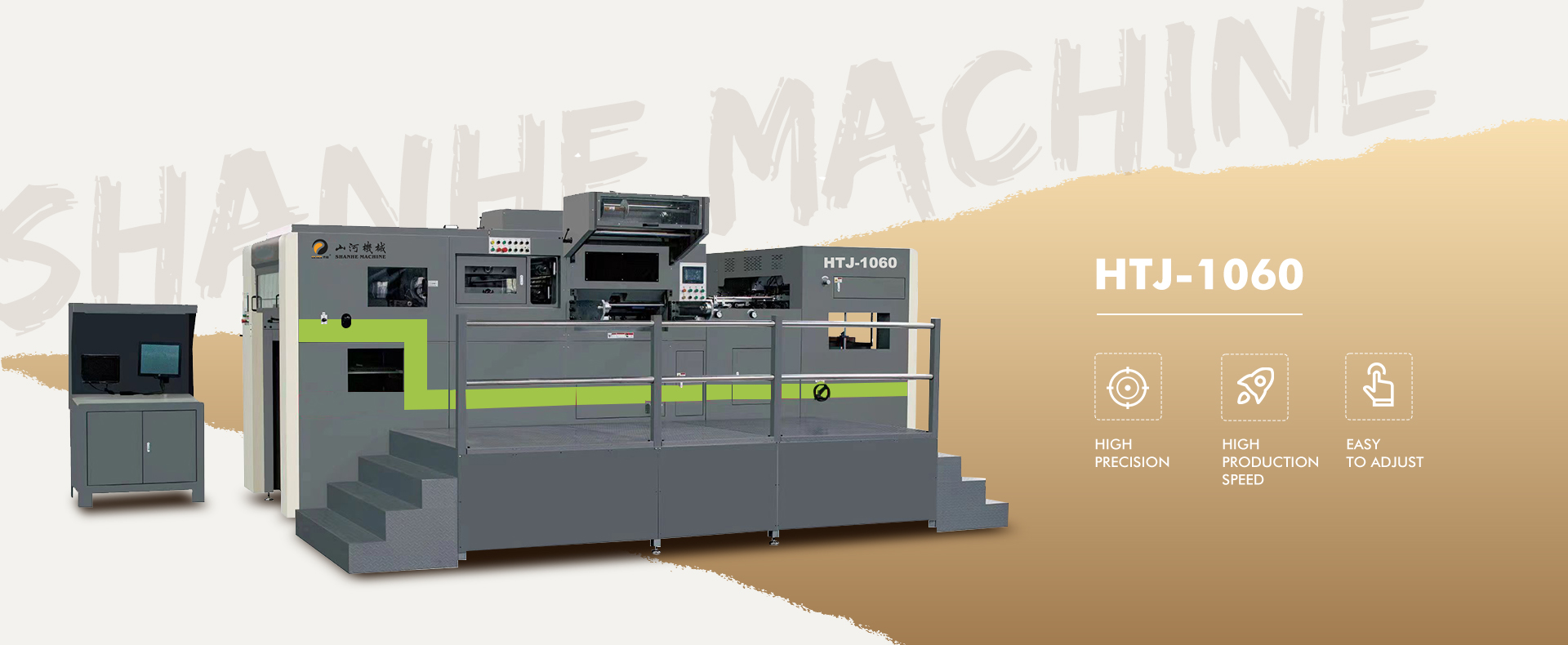

The feeder has a heavy-duty, distinctive design that has powerful suction and can easily send out cardboard, corrugated, and gray board paper. To increase the stability of the suction paper, the suction head can continuously change the suction angle in response to how the paper is deforming. Functions for accurate use control and simple adjustment are available. Precise and reliable paper feeding for both thick and thin paper.