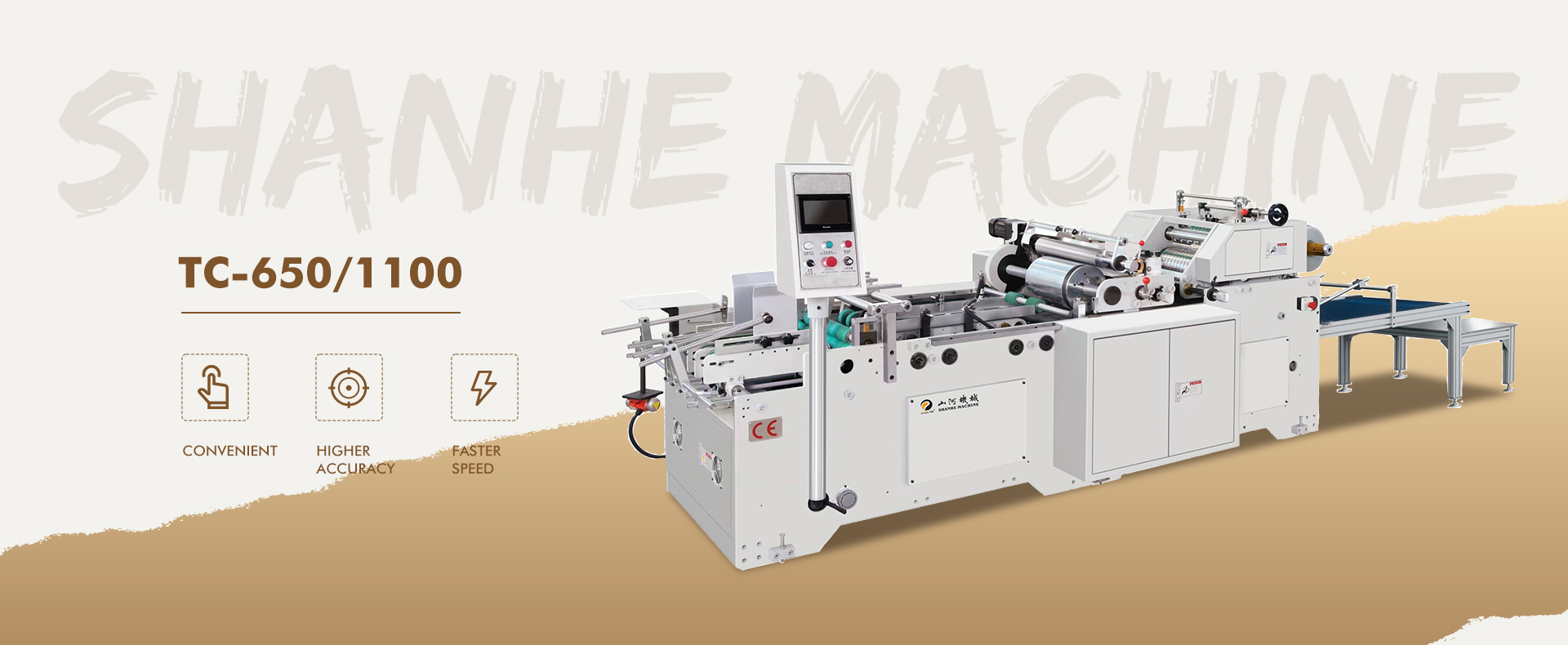

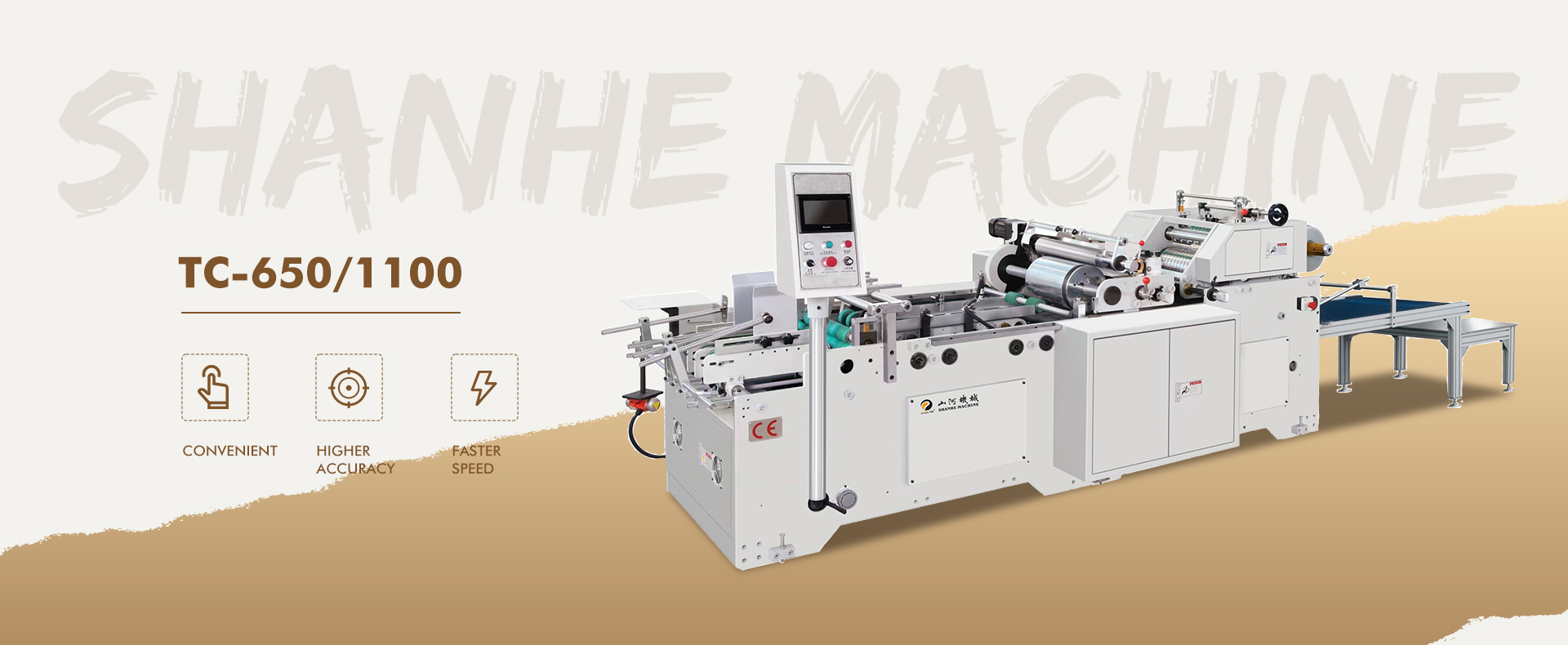

Using servo linear drive, the length of the film input through the touch screen. With the rolling knife, the film can be automatically cut. The sawtooth line can be automatically pressed out and also cut out the mouth of film(such as facial tissue box). Using suction cylinder to hold the cut film onto the blank, and the position of the film can be adjusted without stopping.