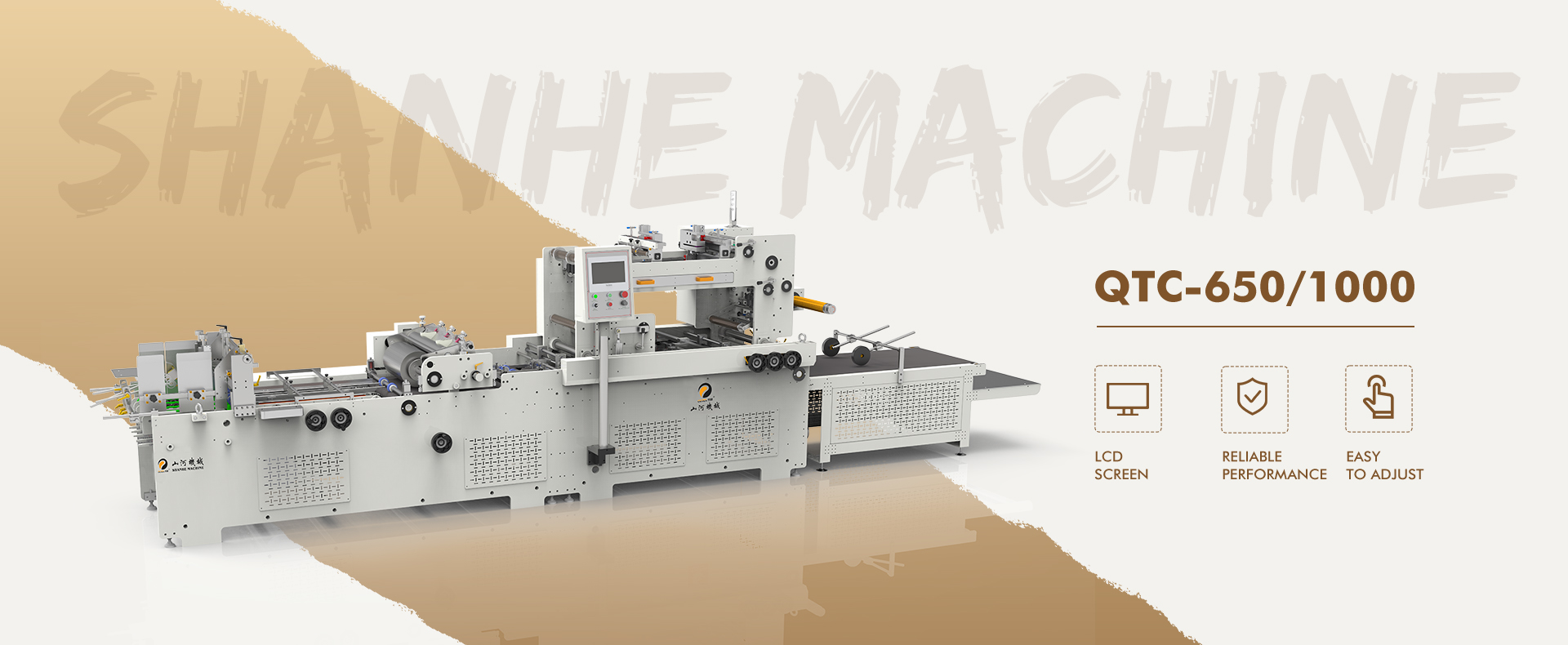

Touch screen panel can show various message, settings and other function.

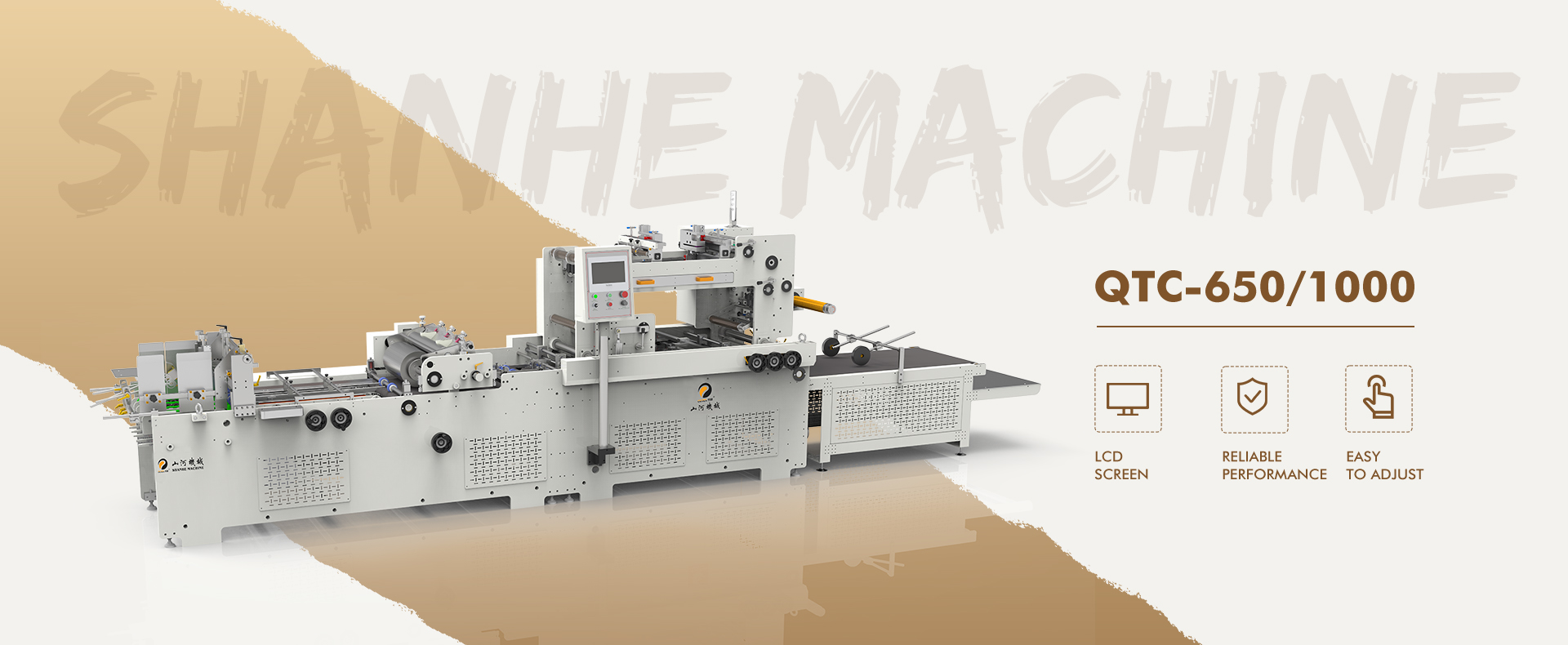

Using timing belt to accurately paper feeding.

The position of glue can be adjusted without stopping the machine.

Can press double line and cut four V shape, it is suitable for double side folding box (even 3 sides window packaging).

The position of film can be adjusted without stopping running.

Using human-machine interface to control, it is easy to operate.

Position tracking using fiber optic technology, accurate position, reliable performance.