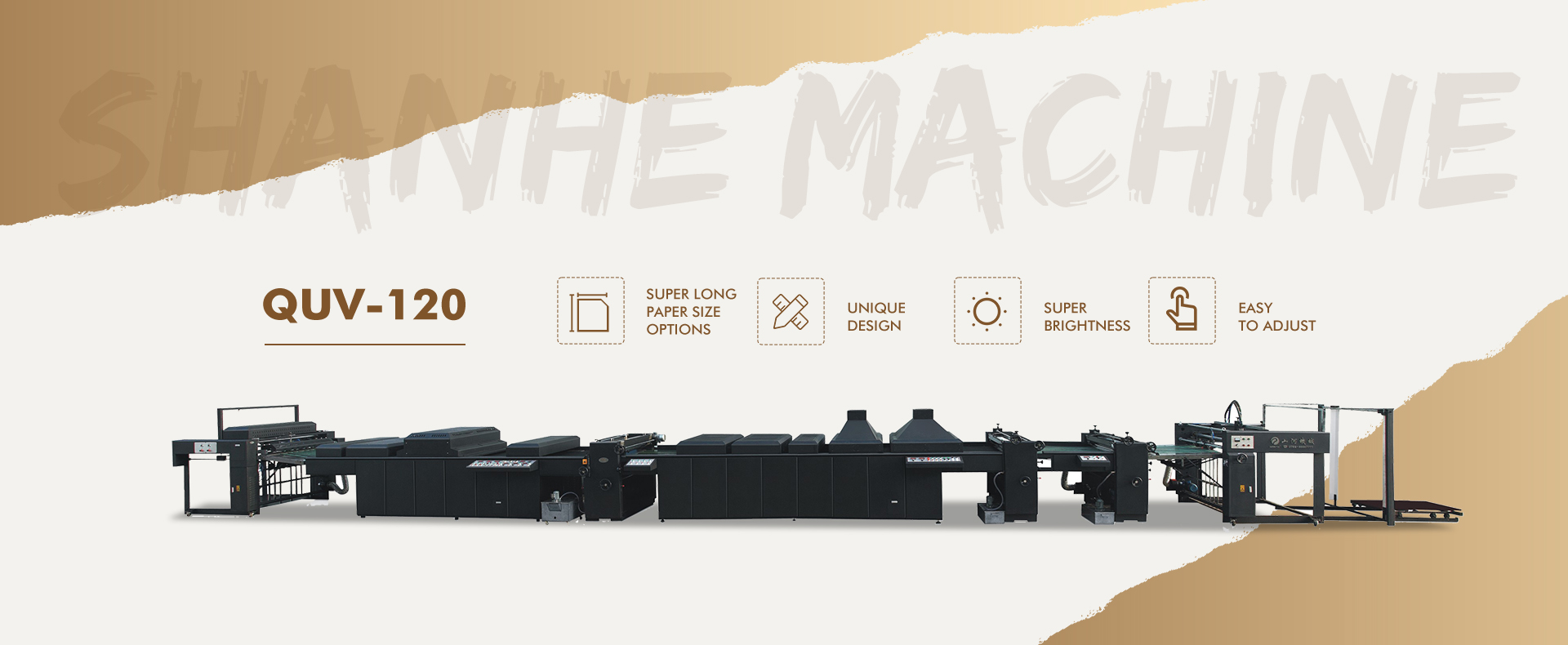

A. Main transmission part, oil limiting roller and conveying belt are separately controlled by 3 convertors motor.

B. Papers are conveyed by imported Teflon net belt, which is ultraviolet-proof, sturdy and durable, and will not damage the papers.

C. Photocell eye senses Teflon net belt and automatically corrects deviation.

D. Machine’s UV oil solidification device is composed of three 9.6kw UV lights. Its overall cover will not leak UV light so that the solidification speed is very soon and the effect is very good.

E. Machine’s IR dryer is composed of twelve 1.5kw IR lights, which can dry oil-based solvent, water-based solvent, alcoholic solvent and blister varnish.

F. Machine’s UV oil leveling device is composed of three 1.5kw leveling lights, which can resolve UV oil’s stickiness, effectively remove product surface’s oil mark and smoothen and brighten the product.

G. Coating roller uses reserve-direction coating way; it is separately controlled by convertor motor, and via steel roller to control the oil coating amount.

H. Machine is equipped with two plastic cases in circular offering oil, one for varnish, and one for UV oil. UV oil’s plastic cases will automatically control the temperature; it has better effect when interlayer uses soya oil.

I. The rise & fall of UV light case is controlled by pneumatic device. When power is cut, or when conveying belt stops working, UV dryer will automatically lift up to prevent UV oil solidification device burn papers.

J. The strong suction device is composed of exhaust fan and air box which are under the UV oil solidification case. They can exhaust ozone and radiate the heat, so that paper will not be curl.

K. Digital display can automatically and accurately examine output of single batch.